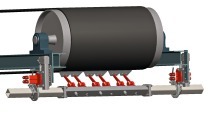

HOSCH scrapers for more sustainable conveyor systems

HOSCH scrapers achieve an exceptionel high cleaning performance

HOSCH scrapers achieve an exceptionel high cleaning performance

© Hosch

This material is not only lost as a product but also causes contamination and material build-up along the conveyor. This leads to increased wear on system components and additional dust emissions. Furthermore, there are costs associated with regular cleaning efforts. If these are neglected, it can, in the worst cases, lead to damage or failures of the conveyor system, such as jammed rollers or misalignment. Every system operator is familiar with these tangible operational and economic impacts. Efficient belt cleaning systems can reduce and sometimes even completely avoid these issues.

Internal studies have now compared the cleaning performance of HOSCH scrapers to the American CEMA Standard. This standard includes four efficiency classes (CEMA Level I to IV) to evaluate the performance of scraper systems. An evaluation of over 1000 field tests revealed a clear result: HOSCH scrapers achieve up to three times higher cleaning performance than what is technically considered possible according to the CEMA Standard (Level IV). As a result, users benefit not only from increased system lifespan, reduced labour costs and fewer unplanned downtimes, but also from the increasingly important reductions in energy consumption and dust emissions, which significantly contribute to sustainability.

To verify these benefits for your own system, HOSCH experts offer carryback measurements upon request. This ensures that promises are backed by measurable results.