Efficient conveyor belt cleaning

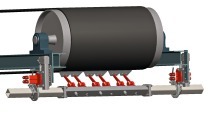

Conveyor belt cleaning systems, so called scrapers, are installed on conveyor systems to scrape the remaining bulk material off the return strand of conveyor belts. At the discharge chute, bulk material remains stick to the belt surface due to adhesion and other factors. Unless removed, the material will pile up under the belt and thus cause additional work and high costs for the operator.

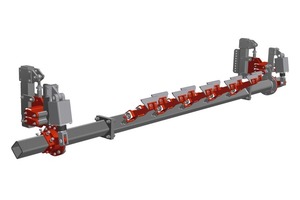

HOSCH-Fördertechnik Recklinghausen GmbH presents at SOLIDS Dortmund 2014 not only the scrapers of the C series, different pre- and main scrapers as well as trackers and sealing systems, but also HOSCH products of the latest generation, designed for extremely heavy applications under the most difficult conditions. On the one hand, there is the very robust HOSCH sprung blade scraper Type C4 (Fig. 1), which has been developed in particular for cleaning very wide and very fast conveyor belts. The self-adjusting cleaning modules align to the profile of the belt, which guarantees maximum cleaning efficiency on belts up to 3.2 m wide and up to a belt speed of 7.5 m/s. The predominant characteristics of this modular scraper type are the ease of installation due to the flexible design, the long life of the tungsten carbide tipped blades and consequently, the minimal service required. The scraper is suitable for most conveyor applications because of its ability to be individually set up. In Germany, the scraper type C4 has been running successfully at some major applications in open-cast mining.

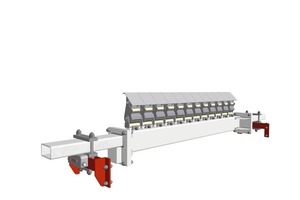

A further display is the great innovative advance in primary scraper technology to be used on discharge or head pulleys, the scraper type HD (Fig. 2). These scrapers can be installed on the pulley, even if the bulk material is extremely difficult. The bulk material sticking on the belt will immediately be re-directed to the main material flow. The HD scraper is virtually maintenance-free. One of its major characteristics is the long life of the tungsten carbide tipped cleaning modules. The HD scraper can be installed on any kind of discharge or head pulley. Furthermore in the case of an obstruction or damaged belt surface, the cleaning modules deflect in a controlled manner, and as a result, the complete conveyor belt system is protected against further damage.

Stand F 20

//www.hosch-international.com" target="_blank" >www.hosch-international.com:www.hosch-international.com