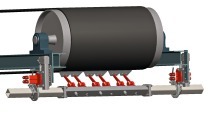

AI-supported monitoring increases availability of conveyor belt systems

The continuous contact of HOSCH scrapers with the belt not only ensures optimal cleaning performance but also enables the collection of high-precision data on the belt surface. HOSCHiris DISCOVER continuously records these measurements, unaffected by vibrations. Any irregularities are automatically detected, transmitted, and displayed, with alarms triggered if values exceed predefined thresholds. Standard features already include online visualization with real-time data, signal history, live video streaming directly from the belt, and cloud access via web browser on mobile phones, tablets, and PCs.

With "spl(ai)ce," HOSCH enhances this solution by integrating machine learning and artificial intelligence. In collaboration with the Swedish company Predge, a new dimension of insight is unlocked from the generated data. Predge, based in Luleå, Sweden, is a well-established partner specializing in edge data science and predictive analytics for industrial applications.

The AI generates a unique fingerprint signature for the conveyor belt, capturing all its individual characteristics. Belt splices are precisely located, and even the slightest changes in data signatures are analyzed. This enables the identification of potential weak points in belt splices that could lead to issues. The further processing of these data sets delivers tailored decision-making recommendations to users, customized to the specific needs of the system operator.

Autonomous monitoring with HOSCHiris DISCOVER and "spl(ai)ce" offers an efficient solution for reducing operating costs while enhancing the safety and availability of conveyor belt systems. Moreover, this digital solution alleviates the strain on typically limited service resources, freeing up time and manpower for more critical tasks.

Booth 6-A47