Coarse and abrasive bulk materials are a constant challenge for conveyor technology components. This also applies to tube conveyors, where conventional deflection systems, such as simple deflection corners or deflection pots, are generally subject to high wear when abrasive material is conveyed. The new patented SFA60 diverter station from Wessjohann Fördertechnische Anlagen provides a remedy here. The bulk material is not deflected directly together with the conveyor rope by the specified angle, but is first conveyed vertically upwards into the deflection station. There it falls from the conveyor rope onto the channel-shaped floor. Two deflection pulleys then deflect the conveyor rope from the vertical to the horizontal direction so that it can continue conveying the bulk material lying in the channel. This effectively prevents the bulk material from getting stuck in the gaps, as is the case with conventional deflection systems. The result is a significant reduction in wear and therefore an increase in the service life of the system.

Lining the inner wall of the housing with polyurethane – here in a deflection pot – significantly reduces wear

Lining the inner wall of the housing with polyurethane – here in a deflection pot – significantly reduces wear

© Wessjohann Fördertechnische Anlagen GmbH

Lining the inner wall of the housing with polyurethane – here in a deflection pot – significantly reduces wear

© Wessjohann Fördertechnische Anlagen GmbH

PU coating for even more wear protection

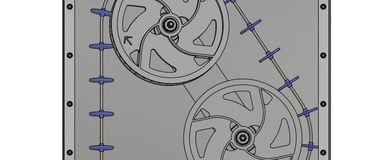

In addition to the new patented deflection station, Wessjohann also offers other innovations that increase wear protection in the tube conveyors. For example, various components are optionally available with a polyurethane coating. This reduces the friction between the bulk material and the inner wall, which also leads to less wear. The friction wheel of the drive unit and the guide wheels are also made of a combination of stainless steel and polyurethane in the latest version. The inner surfaces of the housing can also be lined with polyurethane for both the conventional diverter pots and the new diverter stations. Thanks to these innovations, Wessjohann’s tube conveyors are also suitable for difficult applications, for example in the recycling industry or for other highly abrasive bulk materials.

Lining the inner wall of the housing with polyurethane – here in a deflection pot – significantly reduces wear

Lining the inner wall of the housing with polyurethane – here in a deflection pot – significantly reduces wear