Wear protection for chain conveyors

During the chain conveying of bulk solids, the conveyor can suffer severe mechanical wear, especially when abrasive bulk solids are transported. By coating the steel pushers with a coating of Rhino-Hyde, a high-tech plastic, the North German plastics specialist Arthur Krüger ensures substantially lower wear and a much longer lifecycle.

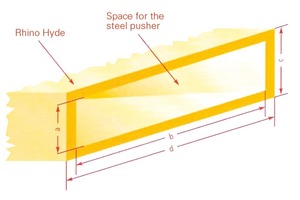

The abrasion resistance of Rhino-Hyde is up to 20 times higher than that of steel. It is also cost-efficient in use as it enables the replacement of individual pusher blocks (Fig. 1) without any need to dismantle the chain. In this way the service lifetimes can be lengthened considerably. The yellow-dyed plastic cover (Fig. 2) has other advantages such as a substantially damped noise level (e.g. for the transport of bulk glass in factory workshops), thermal resistance to 80 °C as well as easy cutting to the required length.

Full corrosion resistance, no sticking of the bulk solids and extremely high cost efficiency are the features of all Rhino-Hyde products: the high-tech plastic generally consisting of sheets is available cut with or without backing in sizes to 3000 x 1200 mm and thicknesses to 25 mm and supplied on site. Pipes and tubes are cold-shaped in the company’s own workshops in Barsbüttel near Hamburg to customer specifications and can be bolted if required.