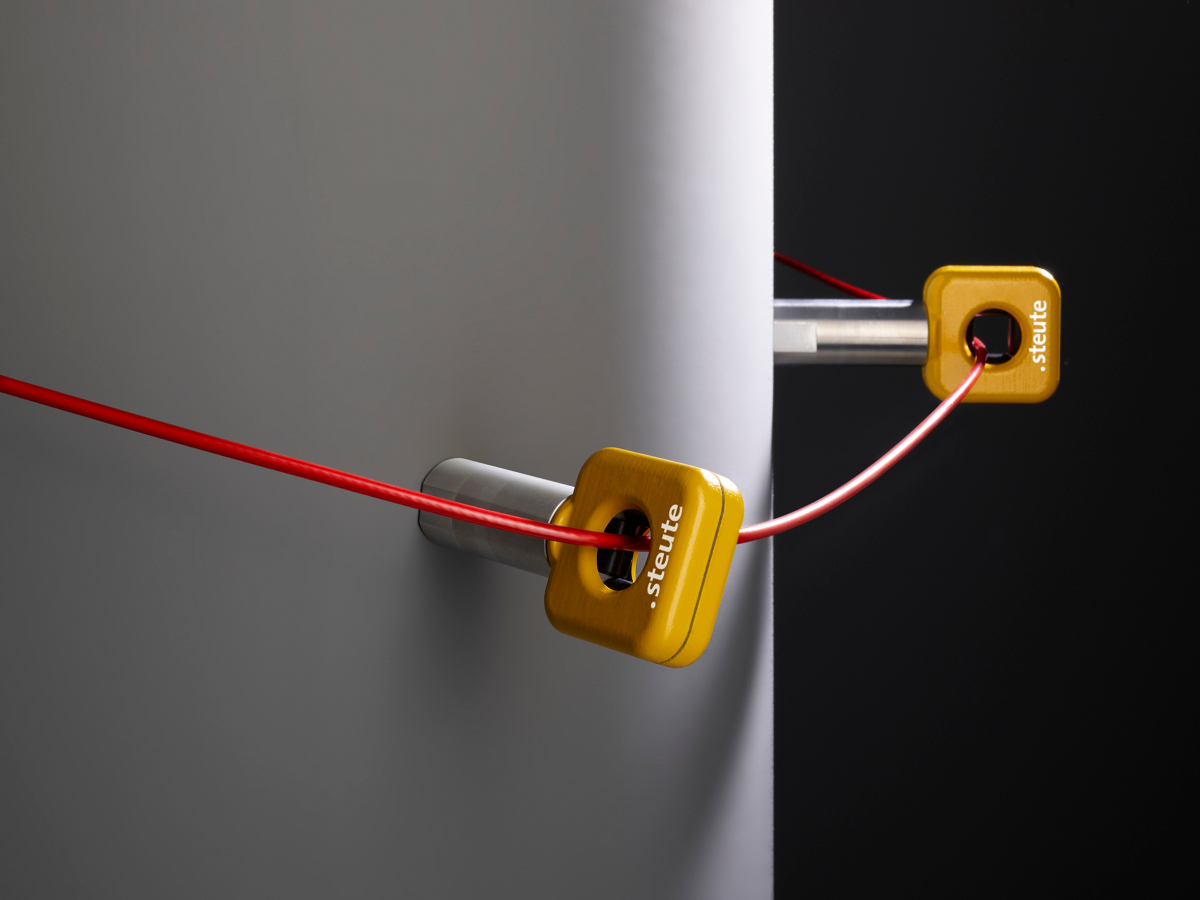

Flexible pulley for multiple deflection of pull wires over longer distances

1 How to make emergency pull-wire switches curve-compatible: with the Multiflex 4R deflection pulleys

1 How to make emergency pull-wire switches curve-compatible: with the Multiflex 4R deflection pulleys

© Udo Kowalski

But how can an emergency-stop function which complies with the standards and is easy to operate be realised along conveyors which go round bends, or in other extensive and non-linear hazardous areas? This question was brought to steute by a manufacturer of airport luggage conveyors. The developers in the steute business division Controltec came up with an equally simple and effective solution which has now been added to the steute range of emergency pull-wire switches: the Multiflex 4R pulley.

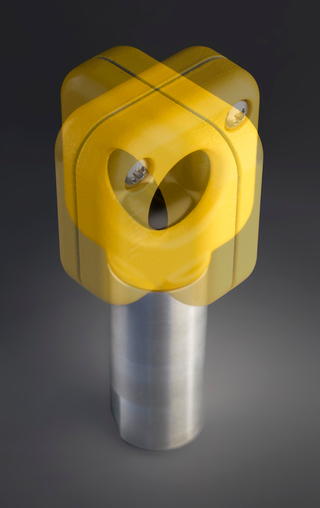

2 Low friction and variable angle thanks to 4 integrated rollers in the rotating head: the new deflection pulley for the pull cables of emergency pull-wire switches

2 Low friction and variable angle thanks to 4 integrated rollers in the rotating head: the new deflection pulley for the pull cables of emergency pull-wire switches

© Udo Kowalski

The head of this pulley, guiding the wire, can be rotated to any position. The Multiflex 4R thus provides a wire guide suited to conveyors which twist and turn in different directions. The important thing here: even when the pulley is deflected multiple times, the friction is minimal, helped by the mobile rollers in the cavity of the pulley. The system complies with a maximum deflection force of 200 N in conjunction with a maximum deflection of 400 mm, as required by EN 60947-5-5. Pulling the “ripcord” to actuate the emergency-stop function is comfortable, wear and tear is minimal, and even longer pull wires can be deflected multiple times without requiring a high actuation force.

An M8 thread in the foot of the pulley facilitates simple and universal mounting of the Multiflex 4R. Alternatively, it can be fixed to conventional profile systems, e.g. conveyor systems for transporting packages and luggage, using a slot nut.

There has also been interest from many other areas of industry using conveyor technology – for example tunnelling. Here conveyor systems transport the stripped material out of the tunnel. An emergency-stop function is guaranteed by robust emergency-stop pull-wire switches. Sometimes the conveyors have to go round bends inside the tunnels, and then the Multiflex 4R is the perfect solution – additional support for the “extended emergency stop” in combination with an emergency-stop pull-wire switch from the steute Extreme range.