Belt conveyors optimized with new transfer station design

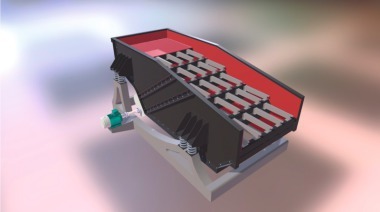

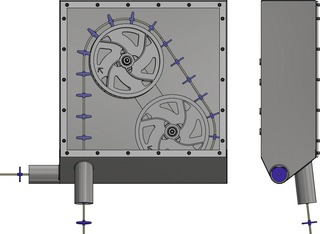

1 Anordnung von 2 Umlenkrollen in der neuen Wessjohann-Umlenkstation SFA60: Eintritt der Förderstrecke vertikal, Abzug mit unterer Rolle horizontal nach links außen • Arrangement of two deflection rollers in the new Wessjohann SFA60 transfer station: Entry of the conveying line vertically, removal with the lower roller horizontally to the left outside

1 Anordnung von 2 Umlenkrollen in der neuen Wessjohann-Umlenkstation SFA60: Eintritt der Förderstrecke vertikal, Abzug mit unterer Rolle horizontal nach links außen • Arrangement of two deflection rollers in the new Wessjohann SFA60 transfer station: Entry of the conveying line vertically, removal with the lower roller horizontally to the left outside © Wessjohann Wessjohann Fördertechnische Anlagen GmbH is launching a new design of its transfer stations on the market. Whereas the abrasive properties of bulk solids used to cause problems in the area of the deflection rollers – all too frequently the flow of product blocked the construction on account of creeping of the filler materials – a Wessjohann innovation currently registered for patent eliminates the susceptibility to this problem in the conveying process. Excessive wear, the associated failures as well as incurred repair costs can be largely avoided with the new SFA60 transfer station for belt conveyors. According to information from the manufacturer, this makes the conveying of coarse, bulky particles – but also of breakable materials – much easier and considerably lengthens service lifetimes.

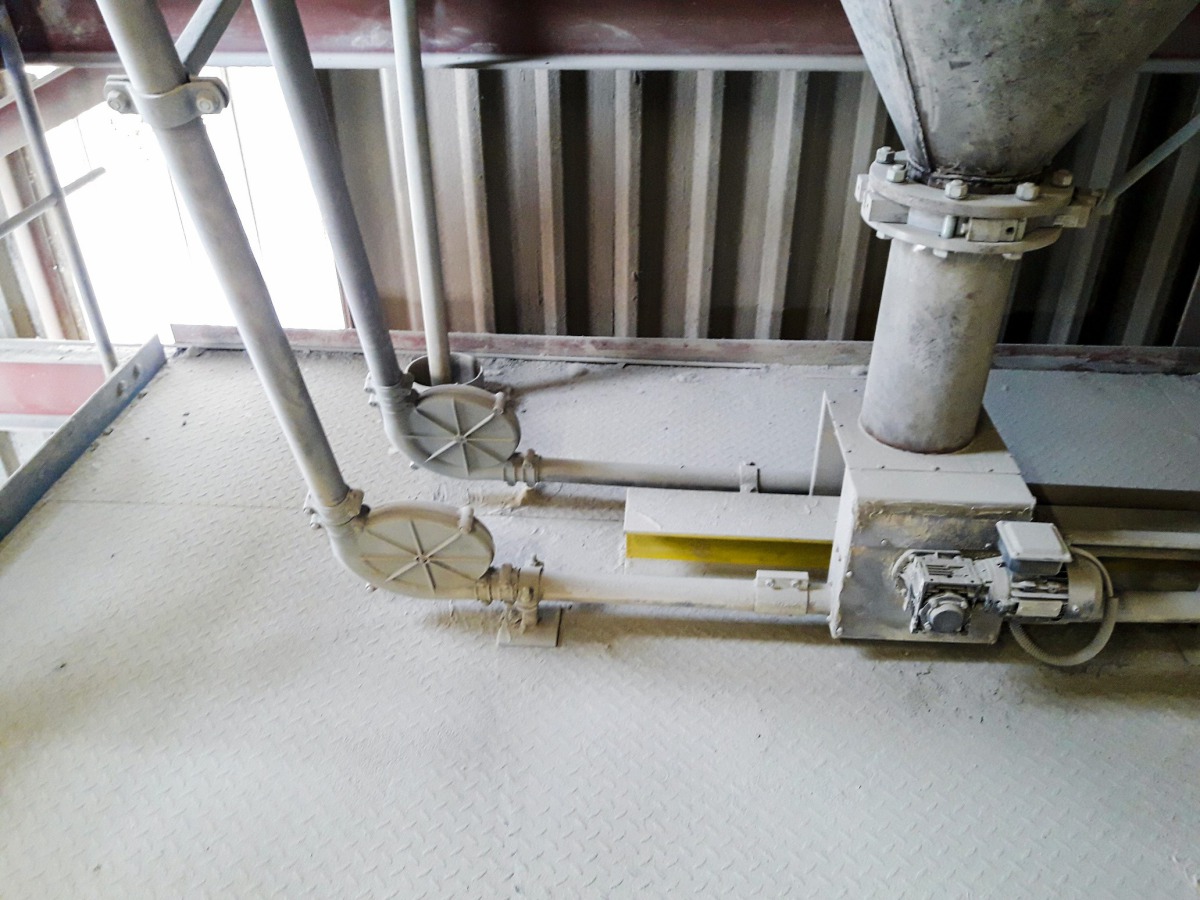

2 Wessjohann-Seilförderanlagen zur Dosierung von Konzentraten nach vordefinierter Rezeptur zur Produktion von Trockenmörtel bei Euroquarz in Dorsten • Wessjohann cable conveyors for metering concentrates according to a defined recipe for the production of dry mortar at Euroquarz in Dorsten

2 Wessjohann-Seilförderanlagen zur Dosierung von Konzentraten nach vordefinierter Rezeptur zur Produktion von Trockenmörtel bei Euroquarz in Dorsten • Wessjohann cable conveyors for metering concentrates according to a defined recipe for the production of dry mortar at Euroquarz in Dorsten

© Euroquarz, Dorsten

The second deflection roller is the solution

While one deflection roller in the housing of the transfer station used to be responsible for deflection and further transport over the conveying line – with all above-mentioned problems, a second deflection roller in immediate vicinity, arranged below the first roller, eliminates the previously frequently occurring faults. With a certain height and side distance from each other, the new roller is positioned in the lower part of the housing. The tram moves vertically into the housing in an upwards movement from below. On this way to the upper deflection roller, the bulk solids fall from the catch plates of the conveying cable (or chain).

With the descent of the conveyor line as well as deflection via the lower roller and now the horizontal section, the conveyor takes up the fallen material and discharges it at the side of the housing. Other design details of the lower part of the housing, such as a tub- or trough-shaped form in the base and inclined housing sidewalls, additionally ensure an ideal situation for catching the collected materials. The drawing tram captures these reliably and ensures largely problem-free conveying. The new Wessjohann SFA60 transfer station therefore stands for considerably reduced wear and longer service lifetimes in the conveying process.