Conveying and screening very hard, coarse-grained and abrasive bulk solids

During the excavation and extraction of natural stone products, ever larger volumes of excavated material are produced. Depending on the geological composition and environmental conditions, this material can be in a very wide particle size range with different particles shapes, which can lead to high wear and clogging of the conveying equipment. Even before this problem crops up, it is possible to start coarse separation on site with the help of a vibrating screen. On the one hand, this enables ordered transport of the overburden in its different fractions and, on the other hand, it efficiently reduces the load fed to downstream discharge and processing machines (e.g. a crusher).

Vibratory equipment is a proven technology which – in comparison with other technologies – scores points with low machine wear. With their rugged and heavy-duty design, especially grizzlies meet the demands of the construction and minerals industry, i.e. primarily handling very hard, coarse-grained and abrasive bulk solids.

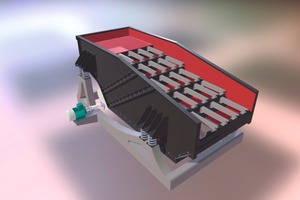

Design and function of grizzlies

At first glance, the structure of the grizzly indicates the ruggedness of the machines. In addition, it combines a wide range of applications. The grizzlies serve as a primary discharge equipment with integrated screen function during discharge or feed hopper discharge, during bin discharge or as a feeder with prescreening to crushers or belt conveyors. Depending on the application, the machines are protected in the feed area with sturdy wear plates and have several bar steps, the solid bars of which are tapered in the direction of conveying and as a result the gap width is enlarged, preventing any wedging of the bulk solids.

A bar screen consists of the following core components:

Screen body with drive traverse

Bar inserts for separation/screening

Bottom and sidewalls with interchangeable wear plates

Drive type: magnet drives, unbalance motors, in the case of a heavy-duty design unbalance exciters

Elastic supporting elements (e.g. springs) reduce the transfer of the vibrations (dynamic forces) into the frame or the surroundings

If a very effective vibration damping is required, additionally a counter-vibration frame can be incorporated

With lengths up to 6000 mm and widths up to 2500 mm, the throughput rate can reach up to 2500 m³/h. A special advantage of the grizzly is its wide range of application, which covers the following areas:

Conveying

Screening coarse grain

Separation of coarse grain upstream of sizing screens

Separation of fines upstream of crushers

Protection of belt conveyors with based on the limitation of fines

Reference project: Coarse separation

of material excavated from tunnel

In a tunnel boring project in Italy, precisely this technology is needed. A large volume of tunnel rubble has to be processed on site to enable its transport off-site and further processing. For this application, a rugged grizzly with over 8 t total weight is the right choice. Basic body, support stand and support bearings are suitably heavy-duty. Wear lining and solid bars made of wear-resistant material ensure a long-life operation of the screen. Size and weight of the machine require the use of unbalance exciters, to guarantee continuous material flow even with fluctuating product feed.

Grobabscheider für Tunnelbruch: Kennzahlen • Coarse separator for tunnel excavated material: characteristics

Antrieb • Drive 2 Unwuchterreger • 2 unbalance exciters

Maße • Dimensions 5500 mm x 2200 mm

Gewicht • Weight 8300 kg

Einbaulage • Installation position Gerät horizontal, Stabrost 5° geneigt • Screen horizontal, bar 5° inclined

Stabrost • Bars Hardox 400

Produkt • Product Tunnelbruch • Excavated material from tunnel

Dichte • Density 1,7 t/m³

Leistung • Capacity 1200 t/h

Korngröße • Particle size 0-600 mm

Trennschnitt • Cut-point 300 mm