Separation solutions for mineral slurries

Vibrating screening machines, hydrocyclones, decanter centrifuges or integrated separation plants – ITE GmbH develops comprehensive solutions for a wide range of industrial applications. Working in close consultation with the customer, the company engineers plants and equipment optimally adapted to the concrete requirements. Plants for processing suspensions for both mobile and stationary operation worldwide are currently planned, under assembly or in operation.

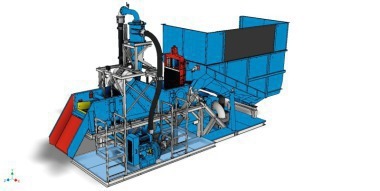

Based on components and technologies tried and tested for many years in deep hole drilling, ITE GmbH has introduced and further developed tailored specialist separation solutions for processing drilling mud and mineral slurries in tunnel and foundation engineering. Whether the job involves processing coarse-grained, abrasive gravel slurries or fine-grained, adhesive clay soils – the Alsdorf-based company supplies the complete range of separation equipment, enabling effective processing of all particle sizes in the size range from 5 mm to ≤ 1 µm. In the past four years alone, the company has built around 150 separation plants (Fig. 1) and dewatering installations. Numerous ITE separation systems are in operation worldwide, working in combination with tunnel boring machines, horizontal and deep drilling machines or shaft sinking machines from Herrenknecht.

In combination with hydrocyclones, decanter centrifuges, polymer dosing stations and thickeners, ITE screen technology provides a complete recycling concept. Even disposal of the critical fines is guaranteed. Fitted with woven steel or wear-resistant polyurethane screening surfaces, pitch-adjustable linear or circular vibrating screening machines (Fig. 2) that operate with acceleration forces up to 6.3 G lead to optimal screening efficiency. The hammer wedge screen fixing system enables uncomplicated exchange of the panel screens. Depending on the particle sizes and properties of the slurries to be processed, the screens can be quickly and flexibly fitted with different screening surfaces with a mesh width from 0.045-5 mm. This ensures optimal screening efficiency at all times.

ITE GmbH’s hydrovacuum cyclones operate with controllable negative pressure. Almost unaffected by changes in the density of the feed flow, they achieve a more constant and dryer underflow compared to conventional hydrocyclones. Generously dimensioned inlet and outlets minimize the danger of clogging by oversize particles.

Thanks to the hydrovacuum cyclones’ low operating pressure from 0.8-1.0 bar, the energy consumption of the feed pump is reduced considerably and wear to the body of the cyclone decreased. Thanks to the low operating pressure, mechanical size reduction and breakdown of the size fractions processed, that is unwanted refining of the solids processed, are avoided. In combination with a controlled, wear-resistant centrifugal pump, high volumes of feed material can be processed in short times. Besides the high capacity, individual regulation of the hydrocyclone feed pressure is another advantage. It can be optimally adjusted to the specific slurry properties.

The compact and high-performance separating plants of TSP series with fine screening systems (Fig. 3) combine the added benefits described above in one product. These plants form a closed, sequential and space-saving recycling system. Key features are short set-up times, easy operation and high flexibility at the installation site. A multi-chamber tank system in stackable container sizes with fixed pipework and a wide range of possible connections forms the optimal substructure.

For the separation of slimes and dewatering of slurries containing fine particles, ITE GmbH relies on centrifuge systems (Fig. 4). Separation is also based on the principle of sedimentation. Thanks to the high centrifugal acceleration, the forces acting on the feed are much higher than in gravimetric sedimentation. In contrast to conventional, widely used sludge centrifuges, ITE GmbH has developed a line of decanters specially designed for dewatering potentially highly abrasive slurries containing mineral solids.

The rugged decanter design with flat conical section, enlarged solids discharge diameter and special screw geometry for high mineral loads meet the requirements for optimal mineral sludge processing. As the drive systems of the ITE decanter centrifuges are designed for high torques, high throughput rates, with exceptionally low wear, can be realized even at higher differential speeds.

The energy-saving, multistage controlled drive with above-average reliability is designed especially for centrifuge drives and guarantees continuous and trouble-free processing even when handling feeds with varying solids concentration. An intelligent, fully automatic and regulation-stable control system ensures consistently high dewatering efficiency and constant logging of all operating parameters. Depending on the specific application, the decanter can be extended with a polymer dosing station and/or thickener to achieve the required separation efficiency.

ITE GmbH, Alsdorf (D), Tel.: +49 2404 67258-0,