RHEWUM high-performance screening machines for the potash industry

Based on decades of experience in screening technology, especially in the potash industry, new materials and technologies open up even more effective and user-friendly processing of the valuable raw material potassium. This is all the more important against the backdrop of limited global resources and currently rising demand in growth markets. Customized screening machines allow maximum production capacities in the range of 0.2 – 40 mm with low maintenance intervals.

Potash is an essential building block of life. Together with nitrogen and phosphorus, potassium is the third essential plant nutrient and an essential component of plant and animal life – it supports plant growth, enzyme activity, protein formation, photosynthesis, respiration and the improved absorption of nutrients. Almost 95 % of all potash produced is used as a fertilizer [1].

A versatile mineral

There are numerous potassium-bearing deposits worldwide, both as chloride, sulphate and nitrate compounds. The chloride-containing form plays the largest role in industry. Potash exists in various compounds, e.g. with sodium, magnesium and calcium (Table 1).

Potash extraction

Potash deposits, which are located at fixed positions and depths of up to 1400 m, are extracted by mechanised methods of underground mining. When underground extraction is no longer feasible due to the depth of the deposits and/or when water inflow problems hinder conventional underground mining, the extraction of salt domes is used. Solar evaporation of brine containing natural potash is the third method of extraction.

Screening technologies in the potash industry

Screening machines are required at various points in the processing chain. Beginning with extraction, the mineral extracted from the mines is first crushed and then pre-classified. The screening machines are then also used for compacting, granulate screening and loading. Screening machines are also used in wet processing, i.e. wet classification and dewatering (Table 2). As screening machines have a considerably lower energy requirement than crushers, they can not only produce saleable product, but also relieve crushing stages (selective crushing) and thus avoid cost-intensive overgrinding [4].

The screening machines used are usually vibration and directly excited screening machines. Vibratory screens are used for high capacities with medium to coarse separation cuts. For critical product properties and separations below 3 mm, directly excited screening machines show their strengths.

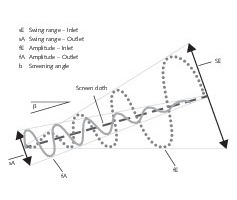

Double frequency (DF) screens are a special type of vibratory screening machines. The drive principle of the DF machine is based on the use of two unbalanced motors with different speeds, which are mounted in the inlet and outlet. The feed material is loosened up in the inlet area by the higher amplitude and sorted according to size (segregation). In the outlet area, smaller oscillations are generated, which increase the screening accuracy by effectively separating out boundary grains (Fig. 1). By changing the direction of rotation of the motors, the conveying speed and thus the screening capacity and the separation efficiency can be specifically influenced. Due to this drive principle, it was possible to create a compact screening unit compared to conventional screening technology.

This screening machine consists of a vibrating inner part and a static housing, which allows fixed connections without failure-prone flexible connections and lower vibrating masses. Together with the external drives a high temperature screening up to 600 °C is possible without any problems. The bolted design allows unrivalled long operating times and a very maintenance-friendly operation, which has proven itself in practice (Fig. 2).

For example, after the first and second crushing stages, two lines of this technology operate at a capacity of 1600 t/h. Pre-separation at 40 mm takes place on a grate – on the screening machine, separation is then carried out at 25 mm, 12.5 mm and 5 mm (Lead picture). Separation at 1 mm is carried out on the directly excited screening machines of the type WAU described below.

DF sieves with compacted KCL

Another field of application for DF screening machines are production screens in compacting. Powdery product enters roller presses together with binding agents. The flakes produced in this way are then broken up and screened. Usually, the crushed flakes contain only about 15 – 23 % of good grain of the 2 – 4 mm fraction. This must be screened at the highest possible capacity and with precisely defined defective grain values.

Loading screening of compacted KCL

This technology has also proven itself as a loading sieve with almost all well-known producers worldwide. A French customer demanded that the dust content of compacted KCL be reduced by almost 10 % to approx. 0.5 % before loading and that agglomerates of 5 mm and more be separated. A 3-deck double frequency screening machine was selected for a feed capacity of 300 -350 t/h. The feed is carried out via an integrated, vibrating distribution device – it allows compact installation dimensions and requires no maintenance.

Direct excited screening machines

For finer separations below 2 mm up to 0.16 mm, directly excited screening machines are used. This machine type is a throw screen with direct excitation of the screen cloth. The screen unit is static. Thus, fixed connections at inlets and outlets are possible. Outside the screen housing, robust vibrators excite vibrations which are transmitted to the screen cloth via vibrating axles (Fig. 3). The high-frequency excitation causes the material to be screened to be discharged at right angles from the screen cloth - the inclination of the cloth determines the transport. Thin-layer screening takes place on the screen fabric at high screening speed. An adjustable cleaning cycle reliably prevents possible plugging of the screenings. Due to the low moving masses (only the mesh vibrates) high accelerations are achieved on the screen lining. These help to overcome adhesive forces with moist or sticky material (e.g. rolling granulate).

In various industrial applications this screening technology is used for pre-screening, cold crystallisation process, flotation and dust removal. Thanks to the functional principle of the static screen housing described above, almost no dynamic vibrations are transmitted into the building. This allows applications even at great heights and enables performance increases in existing buildings without any problems.

Risk of condensate formation

During discontinuous operation or long downtimes, unwanted condensate formation can occur due to moist feed materials. In this case heating coils are often provided to keep the temperature in the screening chamber above the dew point. The heating coils are mounted either on the cover of the screening machine or on the static housing of the distribution device.

Wet classification

Wet classification of potassium requires – as with other materials – short sieve lengths, since with the separation of the liquid no more classification is possible. With the aid of a double feed within one machine, compact units with high screening capacities are possible.

Drainage

Dewatering screens, designed as linear vibrating screens, are used to dehumidify products from wet sorting processes such as flotation and to recover the process liquid. In contrast to conventional screening machines, it works with an ascending screen lining. This results in a much greater layer height and improved solid-liquid separation. Drives with high speeds are used to increase the dewatering effect (Fig. 4).

Process Optimization

Depending on the process used to produce the sales grains, there are sometimes considerable fluctuations due to the differences in the mineral raw material. Increased circulation volumes reduce the product output. Online particle size measurement is of great importance in this context. A partial flow of the produced grain size is led via a sampler into the analysis device, the SizeChecker. A conveyor chute transports the product to a detection unit where the product is optically measured in free fall (Fig. 5). The particle size distribution, as well as long-term trends of the particle size distribution in connection with previously defined limit values are recorded. Control signals are transmitted to external control units via a connected control cabinet (Fig. 6) [5].

![DF screening machines in the pre-screening process underground [3]](https://www.at-minerals.com/imgs/1/5/5/8/7/2/4/tok_234c67d8c4c97eef833311495e785b1f/w300_h200_x600_y398_00_RHEWUM_DF_Siebe_in_der_Vorsiebung_Untertage-6b698388b1656db3.jpeg)