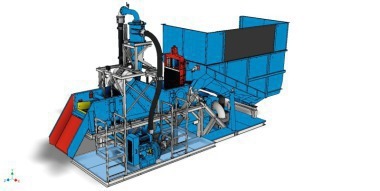

CAB Aufbereitungs- & Verschleißtechnik GmbH

The processing applications so far cover a wide range. They include plants for sand processing with grain size correction, crushed sand washing (concrete & asphalt industry), fine sand recovery, dewatering, slag and waste concrete processing as well as separating plants for tunnel driving and pipe jacking.

“The new DMS 30-150 wet processing plant was designed for the disposal and processing of contaminated suspensions such as drilling mud, road sweepings and similar. The rising demand on the international market to meet current as well as future environmental regulations is the main driver for the development in this area of our work,” explains Managing Director Ing. Mag. Erich Trunkenpolz. “The plants are currently developed for stationary and semi-mobile duties.” The basic operating principle of the plant is based on the separation of a wide range of materials by means of washing/dewatering screen in combination with modern hydrocyclone technology from CAB.

The fully automatic DMS plants work in combination with processing components for waste water incl. neutralization, sludge processing plants and chamber filter processes. Key feature of the plant is the modern control sequences of the individual work cycles and the use of the latest sensor technology to maximize cost and energy efficiency. After the start of the respective work process, the plant runs autonomously, saving costs. The generously dimensioned tipping container enables easy delivery and feeding by all conventional transportation vehicles.

Stand B2.401

//www.cab-group.at" target="_blank" >www.cab-group.at:www.cab-group.at