Wet mechanical processing plant for RC building materials at Max Wild GmbH

If you look at the homepage of Max Wild GmbH, you will see an impressive spectrum of very different services offered by the family-owned company.

It starts with A like demolition of e.g. buildings, industrial plants or bridges. Another very interesting area in the company’s portfolio is entitled Heavy Move – in order to replace or renew industrial components on large industrial buildings and bridges or to dismantle them, special systems such as special constructions, special vehicles (SPMT), strand as well as shifting technology for lifting, lowering and moving are used. Just as with these special applications, Max Wild GmbH is also at home in civil engineering, earthworks, pipeline construction and wireless laying techniques.

But that is not all. In the logistics sector, the company offers, among other things, transports, transport support; construction site traffic and container services. Particularly exciting for the field of processing technology, however, is the area of land recycling: here, the company explores, remediates, transports, processes and recycles. With responsible remediation of contaminated sites and the processing of waste into RC building materials, valuable resources can be conserved, these can be sustainably secured for future generations, and land can be restored and made available for renewed use. In the production of mineral recycling building materials, work is carried out strictly in accordance with the guidelines of the Quality Assurance System for Recycling Building Materials Baden-Württemberg e.V. (QRB) and the specifications of the Baustoff-Recycling Bayern e.V. association. Furthermore, Max Wild GmbH has a system development department for the development of software-based controls and monitoring of components, which has developed, among other things, the new MUDCLEANER for the treatment of drilling mud, as well as a second-hand market exchange.

But how did the family business come to have such a broad portfolio, in which the individual areas complement and support each other perfectly?In 1955, Max Wild founded a small haulage company with which he transported wood and coal. Obviously an idea at the right time, because he soon acquired his first own machines, rented them out and also carried out construction work. Following this example, segment after segment was added in the company’s history. Today, the family business with its headquarters in Berkheim is managed by a total of 5 managing directors in the third generation, and the next generation is also already involved in the company. Around 700 skilled workers are employed in the various divisions of Max Wild GmbH.

One of the latest investments was made at the Eichberg site. This site serves the area recycling division. Here, certified RC building materials are produced from mineral building rubble, road debris, soil and old railroad ballast. The demand for mineral raw materials in Baden-Württemberg alone is around 100 million tons per year. At present, only a very small proportion of this is covered by RC materials. Only 10 million t/a are made available as recycled materials, although more material would be available for recycling. This is a challenge to our near future, which is already being very actively shaped in Eichberg.

In order to be able to better process contaminated soils and remove coatings adhering to the stones, the idea of a wet mechanical processing plant was born. Dr. Gregor Silvers, Business Area Manager for Surface Recycling, already had initial plans for this in the drawer when the practical implementation of a soil washing plant was considered. After extensive research and discussions, the choice for the execution of this project fell on ASE Technik AG. A company that develops and builds individual solutions in the stone and earth industry. These are customized plants in the areas of gravel, crushed stone, recycling, washing plants and sand processing. Founded in 1985, the company takes care of engineering, general planning, plant construction, installation, maintenance and service. In cooperation with the company VHV Anlagenbau, ASE supplies high-quality and state-of-the-art materials handling technology.

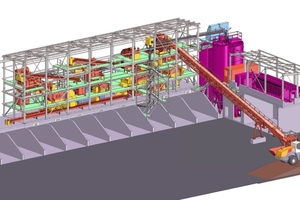

In February 2020, ASE Technik AG began construction of the new production facility on site. This step was preceded by a planning phase of about one year. The complete plant consists of a feed hopper that can be accessed from both sides by wheel loaders. The adjoining central charging conveyor is equipped with a magnetic separator to separate all metallic foreign bodies. In order to wash the heavily contaminated material, ASE has installed a log washer, which dissolves even heavily clumped material. Light materials, such as wood and plastic, are also washed out in the log washer. The washed aggregate is fed to a screening machine and the 0/4 sand fraction is separated. This is dewatered on a screening machine and stored in a silo box. A VHV double belt conveyor vertically conveys the remaining material back to the top. In the following setting machines, light materials are once again removed from the rock material before it is classified into different size ranges by several screening machines and stored in silo boxes. The material discharge is equipped with a large number of metering flaps so that any mixture of aggregates can be produced.

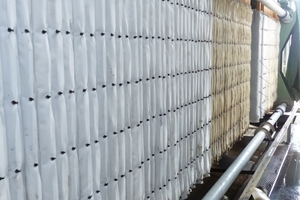

The process water used for the washing process is recirculated so that only a small amount of fresh water needs to be used to operate the entire treatment plant. This fresh water is obtained from the surface water occurring on the site. A separate wastewater treatment plant was built to purify the washing water. Flocculants are added to the sludge water. The required amount of flocculant is determined once a minute by automated tests of the water turbidity and dosed accordingly. With the addition of milk of lime, the pressing times of the chamber filter presses that now follow can be optimized to separate the very fine solids in the wash water. This pressed sludge (filter cake) is disposed of.

In September 2020, the new plant went into operation. The plant was designed from the outset to have reserves for further growth. At the Eichberg site, contaminated material that cannot be processed in the dry state is now being turned back into a source of raw materials for asphalt and concrete plants by means of the wet-mechanical processing plant.

AT: Why did you choose ASE as the plant manufacturer and the log washer?

Dr. Silvers: In the original idea, we wanted to buy the individual components and build the plant ourselves. I had the idea for such a plant for some time and also had a concept in the drawer. I actually came across ASE Technik AG through an Internet search.

Max Wild: The visits to reference plants in Switzerland showed us that such a plant, as we wanted to put together, already existed ready designed. When we took a closer look at the reference plants, we said to ourselves, this is what our plant must look like. And that’s why we chose ASE Technik AG.

Michel Kleisli: We have a number of reference plants in Switzerland in gravel, sand and soil processing, where we can show potential customers on site how they work. We visited four plants with the Max Wild team.

AT: What was the decisive factor in wanting to build such a washing and processing plant here at the site?

Dr. Gregor Silvers: We had 150 000 tons of track ballast here in the yard. The pile was unimaginably large. It was always the idea that we would develop this site as a DK 1 landfill. We had already done a lot of investigations. The problem was that we couldn’t drain off the leachate in a sensible way; existing wastewater treatment plants were out of the question for this because of the quantity. The idea was then to build a washing plant and use the leachate/surface water for this. And then it happened very quickly, within four weeks the decision was made.

Max Wild: We solved two problems at once, the excess water goes into our scrubber and we can process contaminated material wonderfully and that can be sold and used again as high-quality material.

Michel Kleisli: We calculated the water consumption in advance, and in fact we have a zero footprint, i.e. we need exactly the amount of water for the washer.

Dr. Gregor Silvers: But to be on the safe side, there is also a cysterne with 1800 m3 here on the site, from which the wash water can also be supplemented. We don’t have to discharge anything into the Rot, our nearby stream. For the washing plant, we only have to replace the water that sticks to the stones after the washing process.

AT: How is the utilization of the plant ensured?

Max Wild: The political aim is to recycle material before it is dumped. The plant is well utilized and in the future the strategy will be much more in the direction of recycling. In fact, we still get a very good aggregate out of contaminated materials that look more like soil. Other users still landfill this, but after 2035, for example in Baden-Württemberg, this will only be possible in existing landfills, and these actually only have a few capacities left.

Dr. Gregor Silvers, you were involved in the conception and procurement of the plant from the very beginning. How did the commissioning go? Did it meet your expectations?

Dr. Gregor Silvers: Already during the installation of the plant, everything fit perfectly, there was no need to drill an additional borehole or modify a part. The day was actually exciting, the moment when the plant is switched on as a whole for the first time. The day of commissioning was awesome, after four weeks we had reached the planned 100 t/h of track ballast without having a material jam or error in that time. Like Swiss clockwork! So far, the plant is running almost trouble-free.

Michel Kleisli: From the plant builder’s point of view, it was also very farsighted to design the plant in such a way that it can still be expanded in the future without any rebuilds.

Thank you for the informative insight into the processing plant.

The ASE soil washing plant in figures

Capacity: 100 t/h

Installed capacity: 900 KW (incl. reserve)

Feed material: 0/80 mm

Final grain size: 0/1, 0/4, 4/8, 8/16, 16/32, 32/63; 63/80

Material: railroad ballast/loaded soil material

Water balance: 220 m3/h

Installation start: April 2020

Commissioning: September 2020

Key component/supplier:

- Log washer

- Setting machines

- Screening machines

- Water treatment

- Conveyor technology

- Control system

- Pump/Cyclone

- Plant engineering