New soil washing plant for mineral construction waste

Subject to antitrust approval, Schwenk and Max Wild will pool the expertise of both companies in the newly established company SW Baumineralik Donau Iller GmbH & Co. KG. The shareholders, represented by Markus Wild and Joachim Kainz from Schwenk, are delighted about the regional partnership and the consistent further step towards resource efficiency.

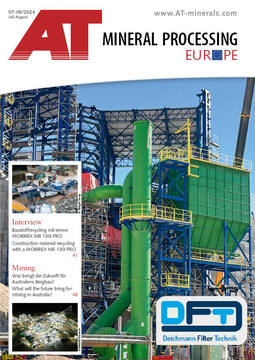

Max Wild has been using a soil washing plant at the company’s own waste disposal centre in Eichenberg (Berkheim) since 2020, making it one of the pioneers in building material recycling. “We were one of the first German construction companies to use building material recycling on a large scale,” emphasises Markus Wild. Since the plant in Eichenberg was commissioned, Profis ohne Grenzen has “washed” 500 000 t of mineral construction waste. Max Wild feeds the sand and gravel fractions recovered during the cleaning process back into the economic cycle as secondary building materials of equal value. The secondary building materials are used in concrete works, basement walls, floor slabs and in the asphalt industry.

“At Schwenk, we see the processing of mineral building materials as an essential part of the circular economy. The high-quality processing of materials allows valuable raw materials to be conserved and high-performance products to be produced at the same time,” explains Joachim Kainz, who is responsible for the Circular Economy & Recycling division at Schwenk. The company is one of the oldest family businesses in the German building materials industry and, in addition to the cement, concrete, sand & gravel and concrete pump divisions, founded the Circular Economy& Recycling division around a year ago in order to develop and promote building material s recycling for Schwenk.

The construction of the new soil washing plant is planned between Ulm and Biberach from August 2024 to the end of 2025. The aim of the new soil washing plant is to further increase the regional recycling rate and thus consistently expand the production of resource-saving building materials. The modern processing plant will process excavated soil and track ballast into high-quality secondary materials such as grains, sands and chippings.