Metso launched Skega™ Life

18.12.2023Metso introduced to its mill lining portfolio an innovative rubber, Skega™ Life, with up to 25 % longer wear life compared to the current premium rubber, Skega™ Classic. The new rubber type is developed in Metso’s own laboratory and validated by field studies. Skega™ Life is a part of Metso’s Planet Positive offering, enabling increased sustainability and safety, optimized throughput, and increased uptime due to improved wear resistance and lower maintenance.

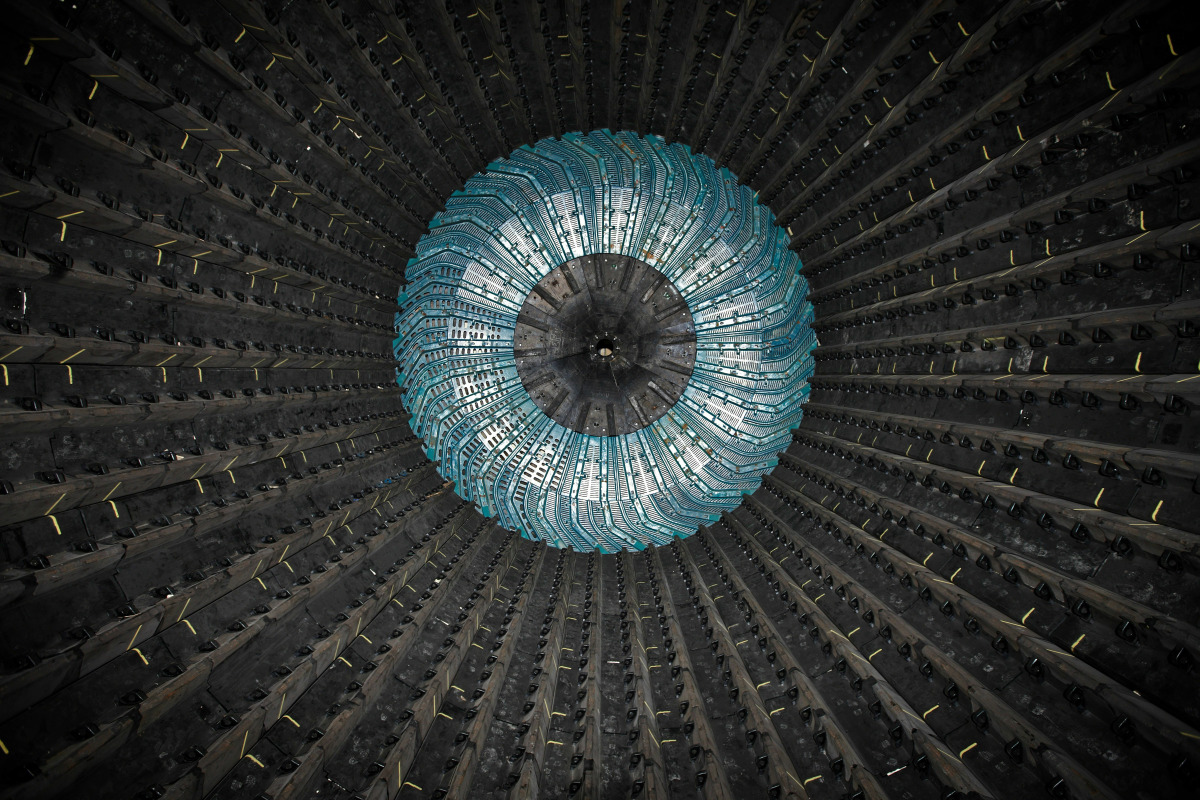

Skega™ Life, a high-performing and sustainable mill lining rubber with up to 25% longer wear life

Skega™ Life, a high-performing and sustainable mill lining rubber with up to 25% longer wear life

© Metso

“We are excited to introduce Skega™ Life rubber to our mill liner portfolio. The new rubber is specially developed to have a very good wear resistance in grinding mills processing high abrasive ores. It can be used anywhere where a customer has a rubber application, but it is most beneficial in ball mills larger than 14 feet, AG, and SAG mills of 18 feet or smaller” says Fredrik Johansson, Global Product Manager, Rubber and Poly-Met mill linings, Metso.

“Mill liners play a crucial role in the mining process and Metso’s liners are always designed by our experts to meet the customers' production targets and the mill conditions and enhancing overall process reliability. Field studies and tests have shown that our new rubber compound can have up to 25 % longer wear life. The longer wear life reduces CO2 emissions and less liner material will end up in the tailings“, says Lars Furtenbach, Director, Research & Technology Development, Metso.

Metso is one of the world leaders in developing and manufacturing high-performance mill liners. Metso pioneered the use of rubber linings and invented Poly-Met™, Megaliner™, and Orebed™ mill linings. New products are constantly being developed to enhance our customers’ ever more advanced processes. The recent innovations include 3D wear scanning, a full Megaliner™ range, trommel deflector, Turbo Pulp Lifter, Liner Positioning System, and a mill liner recycling service.