Vulco® mill lining system increases mill availability and improves throughput

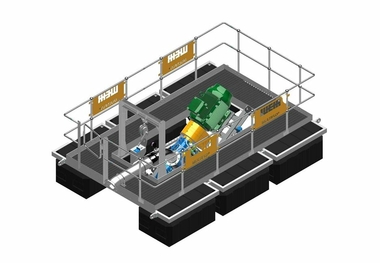

1 Vulco® R63 mill liners installed in the JHP ball mill processing silica

1 Vulco® R63 mill liners installed in the JHP ball mill processing silica

© Weir Minerals

Weir Minerals mill lining specialists, renowned for their expertise in mill lining systems and wear materials, conducted extensive testing and modelling scenarios to evaluate how optimisation of the ball mill charge volume and trajectories would result in an increased mill throughput. Using state-of-the-art simulation technology and drawing on decades of expert knowledge, Weir Minerals specialists designed a customised mill lining system with Vulco® R63 rubber mill liners. The custom-engineered shell liner design ensured correct lifter face-angle to facilitate optimum performance while also increasing the service life of the Vulco® mill liners. Weir Minerals experts also recommended to increase the charge height, significantly improving the grinding process.

The custom-designed solution resulted in increased production and increased mill availability at JHP. The Vulco® R63 mill liners improved wear life by up to 200 %, from 6 to 18 months, more than halving the reline time and associated maintenance costs. As a result of the ball mill overhaul, designed and executed by Weir Minerals experts in partnership with JHP, the throughput was increased by up to 44 %.

2 Vulco® R63 mill liner

2 Vulco® R63 mill liner

© Weir Minerals

Vulco mill lining systems

The innovative designs of Vulco® mill liners are tailored specifically for every customer and are manufactured to the highest industry standards for autogenous (AG) and semi-autogenous (SAG) mills, primary, secondary, and re-grind ball and rod mills. The inherent characteristics of elasticity, high tensile strength and corrosion resistance found in the Vulco® elastomer compounds position them as the preferred mill lining material over steel in many applications.

Key features and benefits

Lighter than conventional steel linings for increased handling safety

Reduced noise due to rubber’s sound dampening effect

Facilitate increased power draw due to reduction in lining weight, increasing filling volume

Increased safety and decreased lining installation hours due to reduced component and lining mass

Faster manufacturing lead times than metal liners