Weir Minerals

Weir Minerals are specialists in designing, manufacturing, delivering and supporting critical process equipment solutions including pumps, hydrocyclones, valves, comminution equipment, rubber and wear-resistant linings for the global mining, mineral processing, sand, aggregates and industrial sectors.

Through a customer-focused strategy, Weir Minerals has used its unique technologies to develop an unrivalled range of comminution, dewatering, process water and specialist slurry processing equipment for some of your most critical processes.

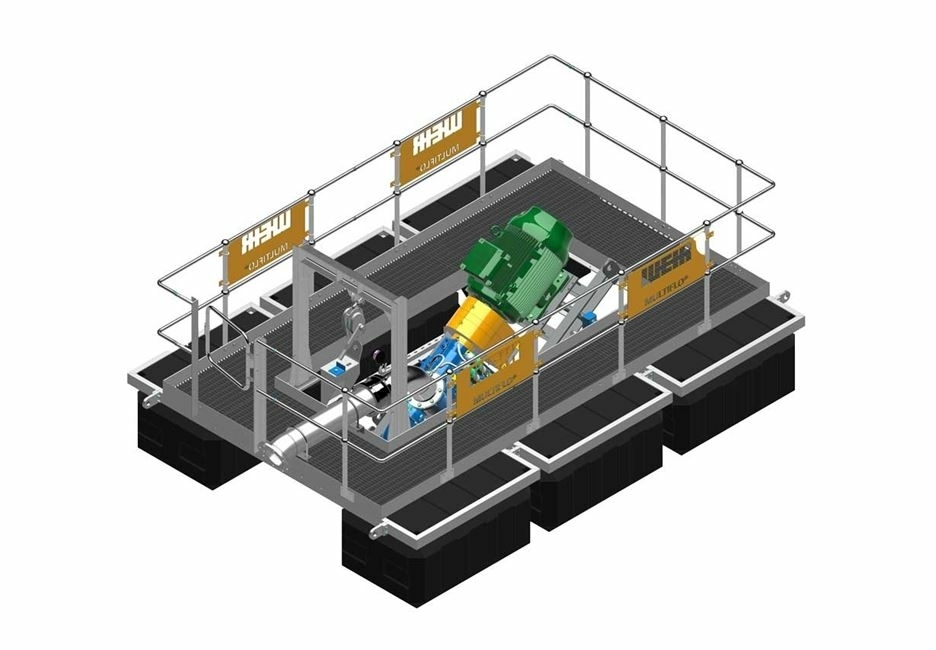

Multiflo® EC (PE) Mono Hull Barge System

Multiflo® EC (PE) Mono Hull Barge System

© Weir Minerals

Weir to unveil Multiflo® EC (PE) Mono Hull Barge System at Hillhead

Weir announced the launch of their ground-breaking product, Multiflo® EC (PE) Mono Hull Barge System, at Hillhead 2024. This product is a state-of-the-art solution for dewatering applications.

The Multiflo® EC multi-float pontoon system is a versatile, galvanized steel frame, designed for ease of shipping whilst offering superior stability and carrying capacity.

The galvanized steel frame is designed to support various Weir Minerals pump types, including vertical, submersible and horizontal pumps.

The design also allows for equipment to undergo normal servicing and maintenance without needing to be removed from the pontoon or take shoreside.

Buoyancy is provided by foam-filled UV-resistant polyethylene floats. They are rotomolded to ensure seamless construction with ribbed reinforcing for superior durability. The foam filling prevents instability and maintains buoyancy in the event of external damage.

The Multiflo® EC pontoon system is designed to support optional extras such as lights and walkways upon request.

Sandmaster™ DP series sand wash plant

Sandmaster™ DP series sand wash plant

© Weir Minerals

Sandmaster™ DP Series of dual-grade sand plants headline at Hillhead

Sandmaster™ DP series sand wash plants feature the same industry-leading technology and benefits of the Sandmaster™ SP series. However, the dual-grade sand plant has added functionality which enables it to create two separate sand products, simultaneously.

The raw sand is fed onto the coarse side of the split-deck Enduron® dewatering screen. The coarse sand is washed on this side of the screen with the aid of spray bars and discharged to the stock pile.

The finer material passes through the screen into the sump. It is then pumped by a Warman® WGR™ pump to the Cavex® hydrocyclone for ultra-fines removal. The fine sand is then discharged onto the Enduron® screen for dewatering and discharged to the stock pile. The coarse and fine sand may be blended using a blending mechanism located on the discharge chutes.

Stand A4