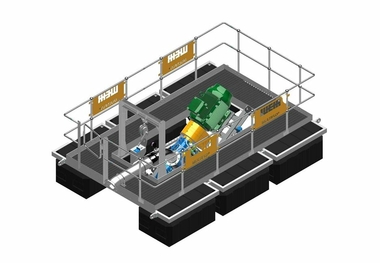

New Multiflo® MudfloTM submersible pump on the market

The innovative solution combines the Warman® MGS pump-end, Multiflo® CB32 hydraulic cutters and ESCO® excavation teeth to provide efficient pumping of highly charged and abrasive slurries. Engineered in Australia, the Multiflo® Mudflo™ pump is available for global customers since July 2021.

Weir Minerals’ unique Ultrachrome® A05 chrome alloy impeller ensures high wear resistance and the specially engineered suction strainer minimises the risk of clogging by preventing large solids and debris from entering the pump. Drawing on decades of Warman® pump design experience, the Multiflo® Mudflo™ pump is capable of pumping between 150 and 1200 m3/h, up to 82 m head.

The Multiflo® CB32 hydraulic cutters feature market-leading ESCO® Ultralok® tooth system to prevent premature breakage, avoid tooth loss and protect the integral locking system to ensure the continuous operation of the pump.

“The Multiflo brand is synonymous with high quality and long-lasting equipment. In designing the Mudflo pump, our dewatering experts drew from the very best Multiflo, Warman and ESCO technology and used advanced hydraulics to create an innovative and cost-effective new solution for mine dredging applications,” Cameron Murphy, Director of Dewatering Weir Minerals APAC said.

The Multiflo® Mudflo™ pump can also be retrofitted to competitor OEM equipment; the quick-hitch plate attachment ensures convenient installation and removal from hydraulic excavators. The pump can be assembled on land, eliminating the safety risks associated with assembling pumps over water. Furthermore, the new hydraulic hose management system reduces the risk of hose entanglement and trip hazards, all the while providing a reliable hose bend radius to ensure smooth oil flow.