Mine operators take control of the water

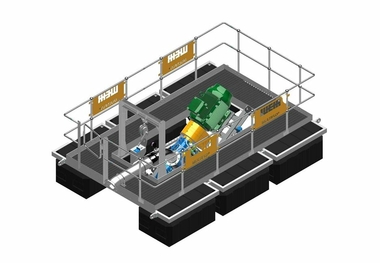

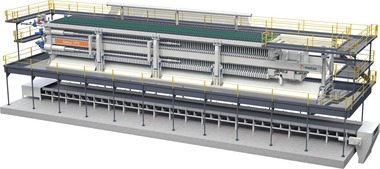

A comprehensive, reliable and flexible dewatering plan is essential to ensuring there is a steady supply of process water throughout the site. Conversely, the removal of excess water from working areas to allow excavation to continue whilst safeguarding the operators and maintaining productivity also requires a dewatering plan. “There is no ‘one size fits all‘ approach to dewatering. It can be an expensive and complex challenge, which is why we deliver bespoke strategies that are cost effective and manageable,“ states Ian Ross, Global Product Manager for Dewatering at Weir Minerals.

Major considerations for any dewatering project

Each site‘s dewatering requirements vary and present unique challenges, with environmental and geological considerations, as well as local climatic variations. Differences in weather conditions and environmental changes can have a significant effect on an operation. The challenges operators face with water will change from region to region. From the outback of Australia where water is scarce, the recovery of water is desperately required compared to the tropical climates of Brazil, where open pits rapidly fill with water, or sub-zero (- 50 °C) arctic operations in Northern Canada that operate year-round – they all require effective water management systems.

The composition of water being moved has a notable impact on the equipment and materials used. The pH range, temperature, corrosive and abrasive content all play a critical role in selecting the equipment to transport water effectively. The presence of solids in the water, the specific gravity, size distribution and content percentage will determine the type of pumps required. Equally, the pipework and valves are also subject to corrosion and abrasion from the products handled and must be designed accordingly.

For every dewatering project, it‘s important the original equipment manufacturer (OEM) understands the environment before developing the strategy, to deliver the optimal solution. The pitfalls of over or undersized equipment include excessive energy use, high cost investment and maintenance and also risk to equipment and personnel, as well as lost production in the case of insufficient capacity. “At Weir Minerals we have a range of flexible solutions that allow us to use several types of pumping equipment, from self-primed diesel driven, submersibles, vertical turbine and multistage to high-wall pump designs for sites that have limited access due to high-sided mine pits. All designs are rigorously tested and include safety features to help prevent risk to operators,“ states Cameron Murphy, Regional Director of Dewatering for Weir Minerals.

With depleting ore grades around the world, there is an emphasis on turning waste into energy, and the dewatering process is no different. Weir Minerals produces equipment which not only dewaters mine sites, but also enables the operator to recycle and re-use back through the plant – ensuring to gain maximum use of its resources.