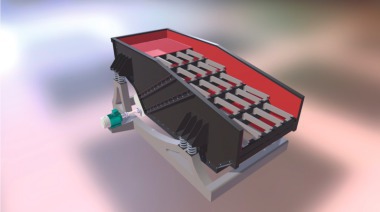

High performance screening machines with many modules

More than 20 000 EuroClass® screening machines made by Ammann (Fig.) stand for excellent product quality, long-standing market experience and technological innovation. Carefully aligned manufacturing processes guarantee a long service life for each machine. EuroClass® screening machines are characterised by their combination of mature technology and robust construction. Their durability and high availability are based on a comprehensive quality strategy. Another advantage of the EuroClass® range is its modular design consisting of a variety of carefully selected standard modules. This makes it possible to meet specific demands such as retrofitting, for instance.

EuroClass® models

·Circular vibratory screens: Suitable for most screening tasks. Available for primary screening, grading, water separation With a single or double excenter shaft

·Elliptical vibrators: Shallow high-performance screens for precise separation. Often used to increase performance in existing plants

·Linear vibratory screen: For primary screening, grading, dewatering, grain size correction, water separation

Benefits at a glance

·Needs-based, economic solution

·High specific output coupled with an excellent degree of separation

·Effective, low-maintenance drive system

·Robust and reliable design

·Use of different screen mats

·Designs with one to five separating cuts, depending on the model

Ammann Schweiz AG, Langenthal (CH), Tel.: +41 62 916 6161, www.ammann-group.com