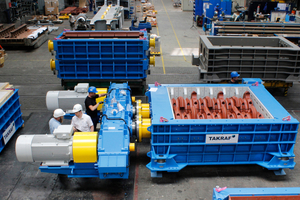

X-TREME Class Sizer for hard rock applications

The TAKRAF X-TREME Class Sizer continue to be in considerable demand with a significant order from Rio Tinto for six machines for the Simandou Iron Ore Complex in Guinea. These machines are currently being manufactured at TAKRAF’s Product & Service Center in Germany. In an important development, a new overlay solution has been incorporated into the sizer, providing superior protection of the base material from wear, resulting in an increased lifetime of wear parts. Known as TAKRAF WolfRAM Armor, the tungsten carbide overlay was developed in-house over a five-year period to provide the sizing teeth with an ideal combination of hardness and ductility as compared to other overlay types. The high level of hardness protects the sizer teeth from “washing” abrasion caused by free-flowing feed material and the ductility of the base matrix provides protection from impact gouging and flaking.

In order to obtain the optimal level of protection from the overlay, TAKRAF works with clients to measure wear rates and patterns on equipment start-up. With this feedback, TAKRAF can revisit the design and optimize the placement and thickness of the WolfRAM Armor. As a result of this iterative process, clients have been able to achieve OPEX savings of over 25 %.

The TAKRAF X-TREME Class Sizer was developed as a new generation of sizing technology to extend the application window of a sizer into harder and more abrasive feed material. The fundamental design philosophy is to maximize the machine’s grip on large lumps. This is achieved by incorporating primary and secondary teeth, crushing ridges, and tooth pockets that let the lumps drop deep between the rolls where the engagement with the rock can be as aggressive as possible. By maximizing grip, the sizer can process oversized feed material and eliminate high wear events where lumps remain bouncing on top of the rolls for extended periods of time. For extra-large feed sizes, classified as feed exceeding 1500 mm, the TCS-X 18 Series (TAKRAF’s largest sizer) can be equipped with the patented rhomboid tooth configuration, which provides a larger pocket for oversize lumps to fall into.

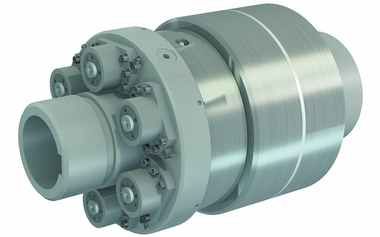

Other features that ensure extended reliability and increased availability in the most extreme applications include integrally cast tooth holders and shrink fit keys that transmit the high crushing forces required to break hard rock lumps. The machine’s heavy-duty bearing assemblies are sealed with a triple labyrinth taconite seal for bearing reliability, while the robust gearbox is designed with high application factors to transmit the required torque and withstand shock loads from uncrushable material.

The machine is also engineered for optimal maintainability to ensure that it can be brought back into production as quickly as possible and minimize downtime. The machine’s modular wear components are easy to handle, with change-out procedures able to be conducted in position. The entire unit slides into its maintenance position for safe and efficient maintenance procedures, with quick-release crushing segments enabling the efficient replacement of individual parts. Worn teeth are replaced in seconds as a result of the bolted tooth system, while the split housing design enables the easy replacement of entire roll assemblies.

By extending the application window of a traditional sizer into hard rock applications, TAKRAF believes that a number of mining operations can now benefit from the advantages of incorporating a sizer into their crushing applications. On September 25th, the TAKRAF Sizer Day took place at the TAKRAF Product & Service Center in Lauchhammer, Germany. At this event, participants were able to learn more about the new generation of sizers and their advantages in hard rock crushing. The attendees had the opportunity to see TAKRAF’s cutting-edge technologies up close, including the robust TAKRAF WolfRAM Armor and our special crushing tooth configurations that are setting new standards in the industry.