Disconnecting safety clutches protect crushers from excessive torques in the event of overloads

In addition to large mining equipment and complete mining systems such as bucket wheel excavators, crushing stations, conveyor bridges and spreaders, TAKRAF also develops and manufactures conveyor technology, crushers and processing plants. The company is headquartered in Germany and operates branches and production facilities around the world to meet the needs of its customers in the mining, port and heavy industries.

The innovative material handling solutions, ranging from individual machines to complex conveying systems, are widely used in a variety of industries, such as mining, minerals and fertilizer processing, iron and steel production, the energy sector, petrochemicals and port terminals.

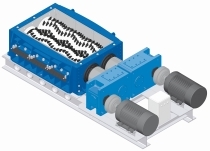

The company’s portfolio also includes primary and secondary crushers. TAKRAF has developed the new X-TREME crusher series especially for ore applications, i.e. for hard and sometimes abrasive material. The feed material is crushed between two counter-rotating crushing rollers, which are driven slowly (with high torque) in the X-TREME Sizer and quickly (with high momentum) in the X-TREME RollCrusher. The X-TREME RollCrusher has proven itself in the processing of oil sand with a throughput of up to 17 000 t/h. X-TREME Sizers are used for crushing various ores (e.g. bauxite, iron ore) at up to 12 000 t/h. Compared to standard crushers, which are used for soft or medium-hard material, the X-TREME crushers are equipped with optimized rollers, more wear-resistant crusher teeth, more robust drives and bearings with improved sealing.

“The drives are designed in such a way that, in addition to sufficiently dimensioned motors and gearboxes for short-term load peaks, they also have integrated high-speed or low-speed flywheels,” explains Dr. Marko Schmidt, Senior Process Engineer at TAKRAF, adding: “These must of course be protected in the event of an overload.” Usually, roll crushers and sizers are protected against overload by a fluid coupling, which is also used as a start-up aid, and roll crushers are additionally protected by a loose roll. However, this is an inert deflection element and has a complicated hydraulic system to ensure parallel deflection of the loose roll. This is why it is only used in the faster-running roll crushers. “It has been shown,” explains Marko Schmidt, “that an additional safety clutch that disengages immediately is required in the drive train, especially with compact foreign material, such as an excavator tooth. Even the fluid coupling is not capable of releasing in the millisecond range in the event of short-term overloads.”

Safety clutches are used in roll crushers with fluid couplings when additional flywheel masses are provided in the drive train to buffer the load peaks during crushing. In the event of an overload, for example due to the feeding of tramp iron, the safety clutch can effectively decouple these additional flywheel masses and protect the drive train – in particular the gearbox – from overload.

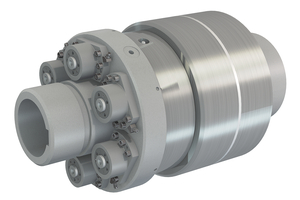

Sizers with frequency converter drive do not have a fluid coupling. For these crushers, a disengaging safety clutch is particularly important as the sole protection against excessive torques. Clutches from the EAS®-HT lastic series, for example, consisting of a safety clutch and flexible compensating clutch, are used here. This clutch combination from mayr® power transmission is positioned between the motor and gearbox and reliably protects the drive. In fault-free operation, the positive-locking safety clutch transmits the set torque backlash-free and with high precision and reacts with exact shut-off and repeat accuracy in the event of an overload.

“If the set limit torque is exceeded due to unforeseen blockages, the clutch disengages,” explains Ralf Epple, Product Manager at mayr® power transmission. “The input and output sides are completely disengaged within a very short time, allowing the stored rotational energy to run out freely.” In general, disengaging safety clutches based on individual overload elements offer protection for drives with very high torques in a compact installation space. They are suitable as torque limiters for heavy and high-speed drives of all kinds and allow large flywheel masses to run out freely in the event of an overload.

Safety clutches from mayr® power transmission are made of high-quality materials as standard and have hardened functional surfaces – this is the only way to achieve the required release accuracy and service life. However, like all other standard clutches on the market, these clutches are not designed for use at extremely low temperatures. In order to still offer reliable, technically secure products for extreme conditions, the company has developed a low-temperature version and carried out extensive practical tests. “These tests enabled us to modify the clutches so that they can withstand extreme cold requirements with the usual robustness,” explains Ralf Epple and continues: “The tests carried out in the climate chamber prove that the EAS®-HT special version is fit for use at very low temperatures down to -48 °C.” Among other things, this is relevant for TAKRAF’s X-TREME crushers, which are used at ambient temperatures of up to -45 °C.

mayr® power transmission is constantly expanding the performance range of its safety clutches. The standard range of EAS®-HT safety clutches covers a nominal torque range from 1400 to 440 000 Nm. The most powerful special version currently available is designed for a torque of 540 000 Nm. But this is by no means the limit: safety clutches with torques of several million Nm are possible.