Compact, robust and high-performance - New ERC25-25 eccentric roll crusher revolutionizes primary crushing in underground mines

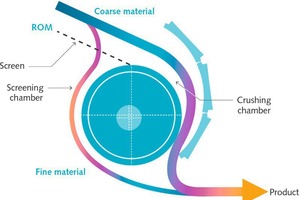

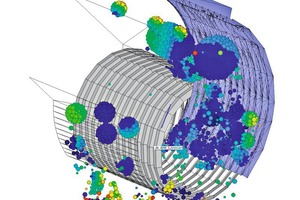

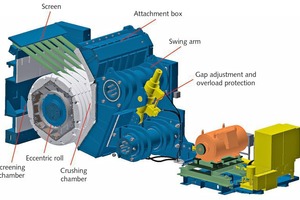

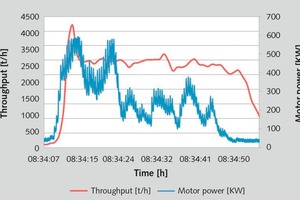

Summary: thyssenkrupp has developed the new eccentric roll crusher ERC25-25. In the following article, the development of the crusher is discussed with the aid of DEM simulations of the comminution processes. After extensive tests had been carried out with the first ERC25-25 under industrial conditions, the most important process and machine parameters regarding throughput, power consumption and product could be determined. Thanks to its particularly flat and robust design and high throughputs of up to 3000 t/h, it is suitable both for operation in underground mines and in the mobile or semi-mobile crushing plants of above-ground applications.

1 Motivation and requirements placed on the new crusher

For mine operators, carrying out the primary crushing below ground and directly at the working face is generally an attractive solution which offers a number of advantages compared to open cast mining. For subsequent processing, the discharged material can be transported from the crusher by belt conveyor systems – an efficient and economical alternative compared to other extraction methods. The challenge for the applied crushing technology is primarily the limited space available in the underground tunnels and caverns, which results in...