thyssenkrupp Industrial Solutions

ERC combines compact design with high throughputs

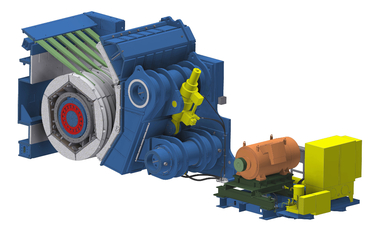

The ERC is a completely new crusher type that effectively combines many advantages in one machine: Its height is 20 – 55 % lower than that of conventional primary crushers for hard rock. This greatly simplifies transportation, installation and maintenance, including underground, and saves costs. Despite its low height, the ERC achieves significantly higher throughputs than conventional crushers. The new series currently includes four models with capacities between 600 and 8000 t/h.

The new design with a roll mounted eccentrically between the screening and crushing chambers and the large, constant stroke of the crusher allow a very high degree of reduction. The integrated screen further increases the efficiency of the machine. Fines are not guided through the crushing chamber but discharged directly to reduce energy consumption and minimize wear to the crusher elements. An automatic crusher gap adjustment system prevents overload.

Low-vibration machine also offers advantages in mobile use

The ERC is suitable for a wide range of applications: With its unique kinematics and innovative screening/crushing chamber design it reduces hard rock and ore particularly efficiently and economically in underground operations and also helps improve cost efficiency in surface mines and quarries. The symmetrical arrangement of the roll allows the crusher to be balanced with great precision. This significantly reduces machine vibrations and the loads on surrounding structures compared with other primary crushers. That means the ERC is also ideal for use in mobile and semi-mobile crushing systems.

Stand B2.203

//www.bauma.thyssenkrupp-industrial-solutions.com" target="_blank" >www.bauma.thyssenkrupp-industrial-solutions.com:www.bauma.thyssenkrupp-industrial-solutions.com