In Pit Crushing & Conveying (IPCC) and material handling system for

the exploitation of an iron ore deposit in Guinea

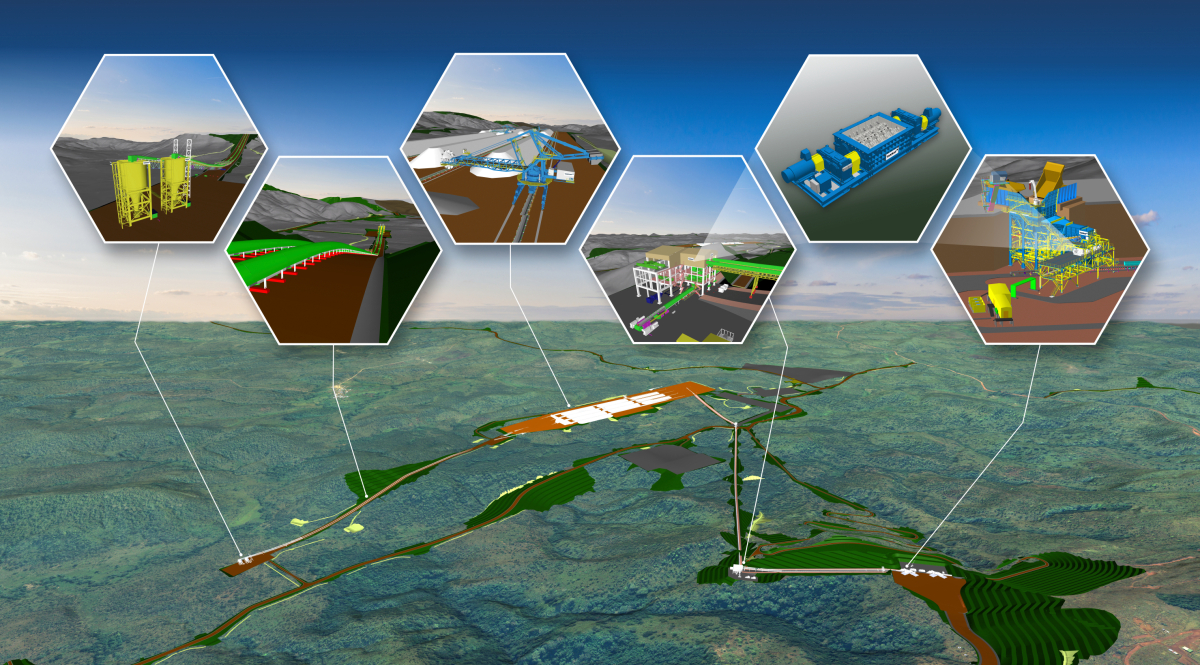

An overall layout of the system at Simandou in Guinea (f.r.t.l.): Two primary In Pit Crushing & Conveying (IPCC) systems incorporating TAKRAF X-TREME class sizers, a secondary In Pit Secondary Crushing & Conveying (IPSCC) system also incorporating TAKRAF sizers, a stockyard with two stackers and two reclaimers, a complex conveyor system with transfer stations linking all parts of the system and two wagon loading stations with buffer silos

An overall layout of the system at Simandou in Guinea (f.r.t.l.): Two primary In Pit Crushing & Conveying (IPCC) systems incorporating TAKRAF X-TREME class sizers, a secondary In Pit Secondary Crushing & Conveying (IPSCC) system also incorporating TAKRAF sizers, a stockyard with two stackers and two reclaimers, a complex conveyor system with transfer stations linking all parts of the system and two wagon loading stations with buffer silos

© TAKRAF

The contract entails the design, fabrication and delivery of an advanced and integrated IPCC and material handling system.

The highlights include:

Two primary IPCC systems incorporating two TAKRAF X-TREME class sizers to crush extracted ore received by truck

A secondary In Pit Secondary Crushing & Conveying (IPSCC) system incorporating four TAKRAF sizers for further ore processing

Two rail mounted stackers for ore stockpiling

Two rail mounted reclaimers for ore reclaiming

Two wagon loading stations with buffer silos

A complex conveyor system with transfer stations for the above equipment, including a technically sophisticated long downhill conveyor between the secondary IPSCC system and the stockyard

Electrical and control equipment and stockyard auxiliaries

In order to achieve the desired annual production rate, the crushing system has been sized with a design capacity of up to 13 200 t/h. Importantly, all stockyard equipment have also been designed with scalability in mind, laying the foundation for future expansions. A separate contract for technical assistance for installation and commissioning of the system, as well as for assistance in longer-term maintenance and spare parts supply will also be concluded.

Thomas Jabs, CEO TAKRAF Group, regarding the award of the contract: “First and foremost, this is an important project for the country of Guinea and we are proud to play our part. Secondly, as steel producers adopt various initiatives to reduce their carbon emissions, the demand for lower-impurity and higher-grade iron ore – essential feedstock for steel production – is growing. Simandou’s premium quality ore will thus play an important role in the global energy transition. TAKRAF has significant experience in IPCC systems and and in delivering solutions that overcome some of the most complex engineering challenges.”