When is a conveyor upgrade actually a downgrade?

When greater production is needed to meet rising demand or when lower quality raw materials require more tons to be processed per unit of output to retain the same level of production, many operators simply speed up the conveyor. Rather than increasing capacity as intended, speeding up the conveyor often results in reduced capacity, because changes in the trajectory of the discharged material can cause build up and clogging of hoppers or chutes, leading to unscheduled downtime.

More tonnage means more carryback, dust and spillage, degrading workplace safety and increasing labor costs for cleanup. Greater volume and weight could also require a more powerful drive, which may weigh more, requiring structural changes and potentially additional space, limiting access for maintenance.

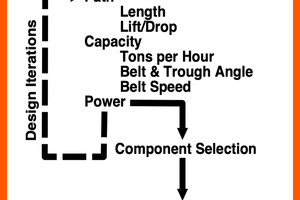

As bulk handling engineers, operators and maintenance mechanics make undocumented or unproven changes, over time, the conveyor operation and physical characteristics can morph the system. In some cases, the proper answer to the question, “Can we increase capacity on the existing conveyor?”...