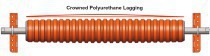

Identifying causes and solving conveyor belt mistracking

The moment a conveyor belt begins to wander, the safety and productivity of the system quickly degrade, and the cost of operation rises. Even a slight belt misalignment can lead to a variety of issues, from small annoyances to full-blown catastrophes involving a conveyor system. However, in the vast majority of cases, mistracking is a problem that can be corrected. Belt behavior is based on a set of principles, which serve as the guidelines for “belt training”.

A misaligned belt can also come in contact with the stringer, causing fraying, shredding or splice damage. If this condition isn’t noticed right away, great lengths of valuable belting can be destroyed, and the structural steel itself can be damaged. In fact, a high-speed belt edge rubbing on the support structure can cut through steel mounts with surprising speed, leaving a razor-sharp edge that poses a safety risk (Fig. 1).

Further, a compromised bracket or support can cause a catastrophic idler failure, which could damage other components of the system. All of these consequences of...