Troughing in conveyor belt loading

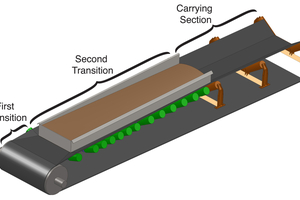

The issue of dust and spillage is quite common at conveyor transitions points throughout an operation’s bulk handling system and can have many causes, including the loading of the belt on the transition. A new, patented concept has been developed to execute an effective trough transition in a short distance. This new approach, which is based on a two-stage transition, is explained below.

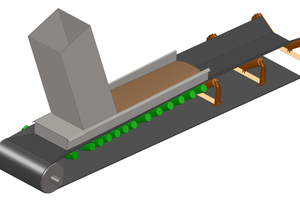

When observing the conveyor transition points throughout an operation’s bulk handling system, the issue of dust and spillage is quite common and can have many causes. If spillage is observed piling behind the system, fouling the tail pulley, or becoming entrapped between the belt and skirt, it could be an indicator of “Loading on the Transition” (Fig. 1). This is when a conveyor belt is loaded before it is in the fully troughed position, which is generally considered bad practice.

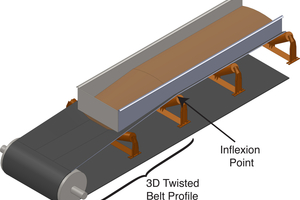

The belt in transition is a three-dimensional surface, and there is an abrupt inflection in the skirtboard angle...