Schauenburg Maschinen- und Anlagenbau GmbH

With the Circular Economy Action Plan of the European Commission presented in March 2020, a first important cornerstone was laid to further raise the importance of topics such as sustainable product design or waste reduction on the agenda. As part of the European Green Deal, the plan promotes the transition from a linear economy to a climate-neutral and more sustainable circular economy and thus declares sustainable growth as a goal. In the long term, the plan aims to become CO2-neutral, sustainable and pollution-free by 2050.

The circular economy is an economic model that focuses on production and consumption, aiming to extend the life cycle of products and thus reduce waste. The focus is on the so-called 3-R strategy: Reduce, ReUse, Recycle. Due to the increasing scarcity of raw materials, especially sand, gravel and water, reducing the use of primary raw materials is a particularly important pillar of the circular economy, especially in the construction industry. This makes the recycling of these very raw materials a significant factor.

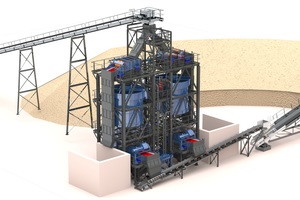

Schauenburg Maschinen- und Anlagen- Bau GmbH (MAB) has been fulfilling its responsibility for sustainability with a focus on the circular economy for over 50 years in the field of environmental and construction material recycling. With its customised plants for the wet-mechanical processing of building rubble, weakly and heavily contaminated soils, road sweepings, railway ballast, etc., the company offers solutions for sustainable management. The aim here is to produce a recycled and high-quality secondary raw material from an environmentally harmful waste material, which has to be disposed of in a time-consuming and cost-intensive manner, and which can be returned to the cycle without any problems.

Optimum separation efficiency during classification as well as high-quality washing to reduce pollutants are the focus here. In addition, the reduction of waste produced in the treatment process ensures that landfill material is reduced, which brings significant financial benefits for the customer. The former waste that used to be generated, for example, during building demolition, thus becomes a new old product and can be described as a material for the future, especially in the resource-intensive construction sector.

Earth Overshoot Day, which takes place earlier every year, shows that economic activity within the planetary boundaries has long since exceeded them and that natural resources are becoming less and less valuable. However, due to the construction boom, the demand for resources is steadily increasing. At this point, RC sands have emerged as a crucial future-oriented field. The use of RC sands not only offers resource-saving and ecological advantages, but the use of recycled sands is also increasingly demanded in public tenders due to their sustainability. Schauenburg MAB’s mobile, semi-mobile and stationary plants enable the production of a recycled sand that can be used as a secondary raw material. Optionally, a correction of the grading curve is further possible, which brings the customer an additional increase in value, especially with heterogeneous feed material.

Thanks to its wide range of products and individual solutions, Schauenburg MAB is able to meet the very different requirements of its customers – the compact containerised plants, for example, offer the advantage of being ready for use even in small installation areas and are characterised by their short installation times and lower transport costs.

The Schauenburg MAB processing plants not only offer solutions for a circular economy through their reprocessing function, they also correspond to the circular economy on the other hand in their design itself, as the Schauenburg MAB plants are known for their extremely good quality and durability. Schauenburg MAB is always a reliable partner for customers with their offer. The company has always been part of the paradigm shift with their flexible solutions and thus living up to the principle: ENGINEERING A BETTER WORLD.

Booth B2.500 and C3.435