German plant and machine engineering changing

As a traditional family company, SCHAUENBURG Maschinen- und Anlagen-Bau GmbH has been developing individual solutions for wet-mechanical processing of ores and minerals, contaminated soils as well as sand and gravel for over 50 years. With solutions for treating mud for tunnel and civil engineering, the company is one of the world’s leading suppliers of separation systems. Reliability and quality have always been the cornerstones of its work, as a consequence of which SCHAUENBURG MAB can today look back on customer relationships lasting decades.

Against the background of increased competition, services have become the crucial factor for the successful realization of projects. From needs assessment together with customers, through working out individual solutions to after-sales – customer requirements are increasing, as are the company’s standards for its services, too.

Besides widely known services such as the dependable supply of replacement parts, maintenance and repair of plants, today there is also potential in monitoring of plant operations. The use of modern means of communication, the development of digital measurement systems and the growing quantity of useful data enable a new type of remote monitoring to help those responsible to quickly make the right decisions during operation in every situation and support the customers. With the continuous capture of process data, information can be obtained on running times, wear and lead times. This ultimately leads to increasing lifetime of operation-critical components and finally to better assessment of the cost efficiency of investments.

Nowadays, project planning is becoming increasingly complex and detailed; especially to precisely assess the cost efficiency of an investment over its entire lifetime and to minimize risks, which affect, for example, process engineering and or operation.

In this context, at SCHAUENBURG MAB, the test centre takes on a key role: With the knowledge that a process development and adaption of the plant technology requires intensive tests on the material processed, the company has continually modernized and extended the existing test centre. The test centre is a salient element in the process from customer enquiry to commissioning and after-sales service. Besides this, it provides support for testing new processing ideas in advance and for deriving decisions from the test findings – e.g. on how new applications can be realized.

With the help of the SCHAUENBURG MAB test centre, tests can be run with customers’ material samples and processes elaborated for customers to solve a problem can be evaluated. This brings customers maximized certainty with regard to process stability as well as the cost efficiency of a planned plant prior to a decision to buy.

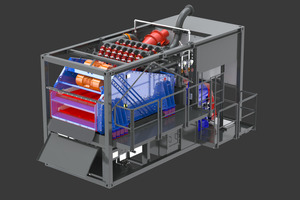

A test run with several tonnes is not unusual. The company test centre offers the possibility to run tests with plant components, like, for example, screens, hydrocyclones, various up-current classifiers, attrition cells, spiral separators, presses, as well as centrifuges and other equipment. Entire processes can be assessed in terms of their process engineering, by combining the individual components accordingly. Key machines in the SCHAUENBURG MAB portfolio are available in several sizes and models.

The customer is always involved in the preparation, running and evaluation of the tests. After completion of the tests in the test centre, the customer receives a detailed test report and, after consultation, a corresponding plant offer. During consultations in the event of an order, the test results can serve as a basis for a process engineering guarantee, providing a fair contractual basis for both sides.

For the design and engineering of plants, a flexible system from customer enquiry through tests in the test centre, test-based design and engineering of the processing lines in the plants has been created. With intensive testing with materials, errors in the design and planning of the plants are minimized. By taking part in running the tests, the customer can see for themselves how their material can be processed with the proposed process equipment and line sequences. Accordingly, already before awarding a contract, the customer is well-informed about all process steps and economic figures, to be able to make a soundly based decision for their project.

Individual solutions

The wide array of individual solutions at SCHAUENBURG MAB for wet-mechanical processing can be basically divided into three primary business areas: Environment and recycling, tunnel and civil engineering as well as ores and minerals, which also includes the sand and gravel business.

In the Environment and Recycling Division, SCHAUENBURG MAB specializes in the development of soil washing equipment for various applications. Be it large stationary plants for remediation of contaminated soils, river and harbour sediments, or modular compact plants: The company ensures that the customers are always optimally equipped for their projects.

Objective of the washing plants is to minimize the material to be landfilled. Most of the “washed” material can often be reused and utilized for a wide range of purposes. The soil washing equipment is always individually tailored to the customer’s requirements – with components that have proven efficient on hundreds of construction sites around the world. The containerized compact plants can be combined with each other and extended. The company has 10“, 20“ and 40“ container frames available as a platform. With the compact container plants, the customer has another important advantage: At many construction sites, space is often a limiting factor; it is not always possible to install large stationary plants. Here the compact design with minimized footprint for the SCHAUENBURG MAB plants in container form really come into their own. Other advantages of this model for the customers are its low-cost transport and very short set-up times.

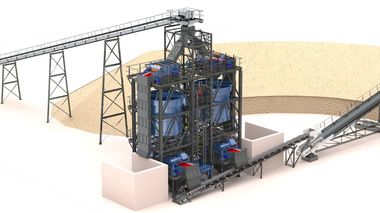

Since founding of the company, SCHAUENBURG MAB has also been working in the processing of ores and minerals and can draw on many references. The ever increasing demand for resources today necessitates the construction of new processing plants worldwide as well as the upgrading of existing systems. The latter to increase capacities, optimize process steps and achieve a more efficient extraction of products. The focus of SCHAUENBURG MAB is the planning and supply of individual components up to turnkey plants.

In tunnel and civil engineering, SCHAUENBURG MAB is a world market leader in mud treatment. The company has supplied customers with separation plants for tunnelling projects on all scales for many years. Whether in microtunnelling or large-scale tunnelling – single and multi-stage separation plants from SCHAUENBURG MAB set standards in respect of quality, efficiency and performance. Small, medium-sized and large construction companies all over the world trust in the company’s technology. From small processing plants with throughput rates of 100 m³/h and less to large plants with throughput rates of 4000 m³/h and more – everything’s possible.

Hall B4, stand 352

Author:

Martin Bunzel, Business Development Manager, SCHAUENBURG MAB