Research & Development, Process Engineering Tests – The HAZEMAG Test Plant

The objective of the HAZEMAG Test Plant is to assist in the optimum planning and design of the company‘s equipment and plants by gathering and providing the latest process engineering techniques. The test plant examines in detail and puts into practice all the latest information and knowledge obtained by its Research & Development (R&D) programme in the form of exhaustive practical testing, in order to replicate actual field conditions as far as possible. The design prototypes of crushers and dryers, as well as other process engineering equipment are subjected to thorough and exhaustive testing in the test plant before they are finally approved for series production.

The experimental work carried out in the test plant is a combination of theoretical and practical knowledge and experience, providing the foundation for solid and optimal plant design and its implementation. The test data thereby generated are applied to the development of machines and plants which can be tailored to meet customers‘ individual requirements to suit their overall plant concept, and form the basis of the guarantee values of the specific process engineering parameters. This is particularly important for the customer, since he can be secure in the knowledge that the machine selected for his particular application is the correct choice.

1. Test Plant facilities

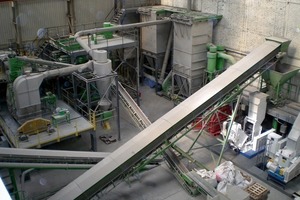

The existing plant facilities (Fig. 1) allow for the equipment to be combined and operated within the following groups: coarse crushing, fine crushing/grinding, grinding & drying, drying and laboratory testing. The machines in the plant are all from the current HAZEMAG range of equipment, to ensure that field conditions are replicated as close as possible [1].

The layout of the coarse crushing section has been designed to permit use on the basis of the two types of impactor or the roll crusher (Fig. 2). If a screen unit is used, oversize material can be returned to the...