Ozone and ultraviolet light shorten the life of conveyor belts

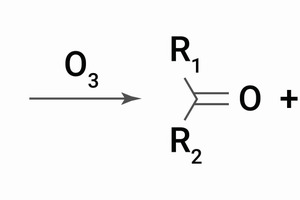

There are many factors that determine the service life of a conveyor belt. These include constant abrasion from the material being conveyed and damage from heavy, sharp rocks falling on the belt or tearing and ripping when a hard, sharp object is caught and penetrates the belt. In addition, there are two other factors that have a major impact on the life of a rubber conveyor belt: Ozone (O3) and ultraviolet light (UV).

However, what is not well known are two other inescapable factors that have a huge influence on the operational lifetime of a rubber conveyor belt. Those factors are ozone (O3) and ultraviolet light (UV)....