Five reasons for replacement of conveyor belts prematurely

Although industrial conveyor belts are costly components, it is increasingly common to see belts being replaced much sooner than they really should be. Here, conveyor belt specialist Leslie David explains the top five reasons for the lack of longevity as well as providing some helpful tips on how to maximize belt life and reduce costs.

1 Wrong specification of belt

One of the most common reasons why so many belts fail to provide a long and cost-effective lifespan is simply that the specification of belt is not correct for the conveyor application and/or the materials and working conditions. So the belts being used simply do not meet the actual requirements. This applies to both new conveyors and ones that may have been running for years. Not only may the belt calculation have been incorrect in the first place, what can also happen is that different belt specifications have been tried over the years, usually in an effort to reduce the frequency of repairs or simply to reduce the frequency of replacement.

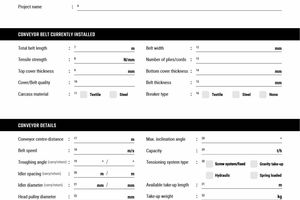

Whatever, the case, selecting a conveyor belt involves making a complicated assessment of all available parameters such as the conveyor system itself including pulley diameters, transition distances, transverse rigidity and much more. Just as importantly, the materials to be conveyed, operational environments and health & safety considerations all have to be taken into account.

For new conveyors the first stage of any belt selection should involve the use of a belt calculation program overseen by a professional conveyor belt engineer. The same applies when a conveyor is proving to be problematic. Before any new belt is purchased and fitted, you need to be absolutely sure that the specification of the belt is correct.

It is just as easy to over-specify a belt as it is to under-specify. Over-dimensioned belts can create all kinds of problems, especially if the tensile strength or the number of plies exceeds what is actually necessary. First of all, the belt will be heavier and less flexible in both length and width than it should be. Reduced longitudinal flexibility usually requires an increase in the diameter of the drive pulley. A tensile strength that is just one step too high would usually necessitate an increase in diameter of 25 % or more. Failure to increase the pulley (drum) diameter can lead to dynamic stress failure, especially in splice joint areas. Reduced horizontal flexibility causes a decrease in troughability.

2 Inadequate wear resistance

The wear resistant quality of the outer covers of a conveyor belt is the biggest single influence on the working life of the belt and consequently its ‘whole life’ economic cost. The choice of cover grade or ‘cover quality’, is primarily influenced by the materials being conveyed, closely followed by the operational conditions. In the world of quarrying and mining, the most common requirements are the ability to resist abrasion, ripping, tearing and impact.

The rubber used for the outer covers usually constitutes at least 70 % of the overall volume mass of both multi-ply and steelcord belts and 50 % of the raw material costs. This makes it the single biggest opportunity for manufacturers to minimise costs and to compete for orders based on price rather than quality and performance. It is a common misconception that a belt specified by a supplier as being ‘abrasion resistant’ should be expected not to wear quickly.

Different causes of wear and abrasion require different kinds of abrasion resistant rubber. For example, belts that transport heavy and/or sharp objects such as rocks, which cut and gouge the belt surface need different resistance properties compared to belts carrying ‘fine’ materials such as aggregate, sand and gravel, which literally act like a piece of coarse sandpaper that is constantly scouring the belt surface.

Abrasion resistance – International standards

There are two internationally recognised sets of standards for abrasion, EN ISO 14890 (H, D and L) and DIN 22102 (Y, W and X). In Europe the longer-established DIN standards are most commonly used. Typically, DIN Y (ISO 14890 L) relates to ‘normal’ service conditions such as sand and gravel. In addition to resisting abrasive wear, DIN X (ISO 14890 H) also has good resistance to cutting, impact and gouging such as sharp, heavy rocks. DIN W (ISO 14890 D) is usually reserved for particularly high levels of abrasive wear often found in crushers for example.

The most important thing to remember when comparing abrasion test results is that higher figures represent a greater loss of surface rubber, which means that there is a lower resistance to abrasion. Conversely, the lower the figure the better the wear resistance. Comparing the wear resistant capabilities of one offer with another is not always easy because technical datasheets provided by manufacturers and traders usually only show the minimum figure demanded by a particular test method or quality standard rather than the actual performance that the belt should be expected to achieve.

It is also important to bear in mind that the ability of a belt cover to withstand wear is not due to its ‘abrasion resistance’ alone. The wear resistance of rubber is a combination of its overall strength, its resistance to abrasion and its resistance to cut and tear propagation. If the latter is very low then a small, seemingly insignificant area of damage in the cover can easily increase due to the continuous material loading and the relentless flexing of the rubber around the drums and pulleys. In time, this damage will connect to another area of damage and consequently a small piece of damaged rubber will effectively be cut out and lost rather than simply worn off.

A final word on wear resistance – whatever cover grade is used, it is absolutely essential that the rubber is fully resistant to the effects of ozone and ultra violet. At ground/sea level ozone becomes a pollutant. Exposure is unavoidable. It increases the acidity of carbon black surfaces and causes reactions to take place within the molecular structure of the rubber resulting in surface cracking and a marked decrease in its tensile strength. Likewise, ultraviolet light from sunlight and artificial (fluorescent) lighting also accelerates deterioration because it produces photochemical reactions that promote the oxidation of the surface of the rubber resulting in a loss in mechanical strength. In both cases, this kind of degradation causes the covers of the belt to wear out even faster than they should. Experience shows that belts imported from South East Asia will almost certainly not be resistant to ozone and UV. Therefore, when selecting any rubber conveyor belt, ozone and UV resistance should be an essential part of the specification.

3 Damage – ripping, tearing and impact

As every conveyor operator will know, when foreign objects become trapped, penetrate the carcass and cause longitudinal ripping, even the strongest, heaviest belts can be quickly destroyed. The same applies when a belt is torn or the carcass is punctured by heavy, sharp materials falling from height. Believing that such damage is unavoidable and trying to save money by fitting low grade belts is certainly not the answer. Using ‘throwaway’ belts is a false economy and simply does not make economic sense, especially when you calculate the cost of frequent repairs and total belt replacement plus the cost of downtime while that work has to be carried out.

In quarrying and mining, the ability to withstand the forces that rip and tear belts is often more important than any other physical attribute. Despite its significance as a key performance indicator, there are currently no internationally accepted test methods or standards for testing rip resistance, which is perhaps one reason why belt manufacturers rarely mention the subject. Fortunately, an international standard for tear strength does exist. The ISO 505:2017 test method measures the propagation resistance of an initial tear in textile conveyor belts, either in full thickness or of the carcass only. The test is intended for application to multi-ply (fabric) belts in installations where there is a risk of longitudinal tearing. Although it is a defined method of testing, there are no standardised performance requirements.

Application-specific construction

Because of the huge disparities between the types of materials being conveyed, the actual design of the conveyor systems and their varied working environments, there is no ‘silver bullet’ answer to the rip, tear and impact damage. For multi-ply belts the only genuinely practical solution is to fit a conveyor belt that has been specifically engineered to resist ripping and tearing and cope with the impact of heavy objects such as large rocks falling from a high drop height much more effectively compared to belts that use a conventional fabric ply construction. Specially woven fabric plies that allow the transversal nylon strands to stretch are used to create a much greater level of resistance. As the trapped object is pulled through the belt, the transversal (weft) strands of the fabric group together into a bundle that can eventually become strong enough to stop the belt. These special synthetic plies are usually more effective than steel when it comes to actually minimising the length of a rip. Another important feature of such specialist fabrics is the ability to absorb punishment caused by heavy impact by dissipating the energy over a wider area compared to conventional fabric.

Specialist belts of this kind are produced here in Europe but beware of cheap imitations. The genuine article has at least three or more times the resistance to ripping and tearing compared to conventional belt as well as being amazingly resistant to abrasive wear at the same time. As a result, these specialist belts will quite literally run for many years, even on conveyors where conventional belts regularly need to be replaced at extremely short intervals. There is a higher initial price to pay of course but their cost over their working life is considerably lower and with the added benefit of far fewer unplanned stoppages for repairs.

4 Carcass failure

Although carcass failure is commonly seen as a reason for premature belt replacement in its own right, there are a number of different causes of carcass failure that could also quite legitimately be categorised as wrong specification of belt (reason 1) and accidental damage (reason 3). When there are impact damage and/or ripping and tearing problems, there is often the temptation to fit a belt with a higher tensile strength and/or a belt with an increased number of plies that is over-dimensioned for the conveyor design – such as a 1000/5 belt, which had been fitted to a 55 m primary conveyor in a quarry handling Gabbro stone. Despite the apparent added strength, the belt was still only lasting an average of 600 hours. The same applies when there are problems such as too much elongation (stretch) or repeated splice failure – but only if the damage to the current belt is due to insufficient load support or if the belt was obviously under-specified in the first place.

Simply increasing the tensile strength or the number of plies can cause more problems than it solves. It’s advisable to getting a completely new belt calculation using a professional belt calculation program before considering any change of belt specification. If there is a piece of spare belt available then it is often a good idea to send a square meter of it for laboratory testing to measure its true properties.

There are two reasons why this is advisable. In belts that have low quality (low cost) fabrics, it is unusual to find a fabric that has inadequate tensile strength. However, although the amount of material used in the longitudinal strands of the fabric may be adequate, the amount of transversal weft material is often kept to an absolute minimum in order to reduce cost. Although the required tensile strength might be achieved, rip and tear resistance is reduced and elongation (stretch) is low. Low elongation may sound good in principle but if the elongation is too low then this can cause problems with transition distances and a general inability to accommodate the contours of the conveyor and its drums and pulleys. Ultimately, this can lead to the premature failure of the belt.

The second reason for checking the true tensile strength of a belt before replacing it is that it is becoming increasingly common for some manufacturers, traders and importers to supply belts that have totally polyester (EE) fabric plies in a carcass that is declared as being an EP (polyester/nylon mix) carcass construction. EE fabric costs some 30 % less than EP fabric. In itself, this may not seem like a great deal but the fabric plies are a major cost component in any multiple ply conveyor belt so using the much cheaper polyester fabric is a big help when trying to achieve the perception of a lower ‘like for like’ price.

The whole basis of using a mix of polyester and nylon fabric is that it has the best balance of mechanical properties including allowing a conveyor belt to run straight and true, to trough, to flex round pulleys and drums, stretch, transversal rigidity, longitudinal strength and much more besides. The use of totally polyester (EE) fabric compromises a whole range of essential mechanical properties*. The biggest danger is that a polyester weft can cause low transverse elasticity, which reduces both the troughability and impact resistance of the belt and also causes tracking issues. (*Author’s note: The use of fabrics made entirely of polyester (EE) has its place in certain belt types and constructions. However, in those cases the declared specification of the belt should clearly be EE and not EP).

5 Inadequate conveyor maintenance

Of all the causes and reasons for belts not achieving the length of operational life that they should, poor maintenance is the most careless and inexcusable. As with using ‘cheap’ sacrificial belts, failing to carry out routine checks and maintenance on a regular basis is a false economy. Badly worn lagging, missing or damaged idlers and seized rollers can result in damage to the belt. Likewise, material build up beneath drums and pulleys is another common sight, often as a result of carry back.

The whole question of conveyor maintenance is a subject in its own right. A daily visual inspection of all the idlers, rollers, pulleys and drums is time well spent. Identifying and fixing problems at an early stage will certainly save on more costly repairs and maintenance later and with far less downtime. It will also help to keep conveyors operating smoothly and conveyor belts running trouble-free for periods that are much longer than it was perhaps thought possible.

Thanks to years of technological advances and development, the effectiveness and value of modern day conveyor belts should be measured over several years rather than just a year or two or even just a few months, as is so often the case nowadays. It is no coincidence that the decline in the level of expectation has been accompanied by the increased use of low-grade belting, especially belt manufactured outside of Europe. The driver, of course, is the desire to reduce expenditure. However, belts that need frequent replacement have exactly the opposite effect. Expecting less means getting less for your money.

Author:

Leslie David, Consultant

Leslie David is a freelance writer and business consultant based in the UK. Having worked in logistics management for 23 years, Leslie David has spent the last 15 years working and specialising in the European conveyor belt industry. During this time he has become one of the most published authors on conveyor belt technology worldwide.