Max Wild GmbH

90 % less water consumption, 90 % less waste and 90 % less recycling and transport costs: At IFAT in Munich, Max Wild will be demonstrating how sustainability and cost efficiency work in horizontal directional drilling (HDD). The professionals from Berkheim in Baden-Württemberg are presenting their in-house innovation Mudcleaner at the world’s leading trade fair for environmental technologies. The recycling technology processes drilling mud from the HDD process and from geothermal drilling. A special highlight: visitors can see the Mudcleaner truck as an exhibit at the trade fair stand.

“IFAT is the right place for us. Because when it comes to intelligently utilising resources in cycles, we have a number of ideas and solutions in store, such as our Mudcleaner Truck,” explains Christian Wild, one of the Managing Directors of Max Wild GmbH. “We even have our recycling lorry with us as an exhibit and will be showing what our lorry can do to process drilling mud at the trade fair. The Mudcleaner Truck is our answer to the demand for more resource conservation and sustainability on the construction site. That’s why we are also offering our recycling solution to other construction companies and local authorities,” continues Christian Wild.

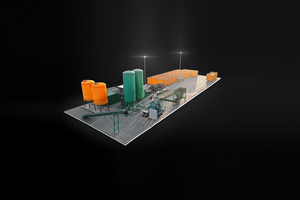

The Mudcleaner technology

Mudcleaner is available as a mobile and stationary system and promises particularly sustainable horizontal and geothermal drilling thanks to efficient drilling mud recycling: 90 % less water consumption, 90 % less waste and 90 % less disposal costs on average for HDD and geothermal drilling. The Mudcleaner Truck is a real all-round talent for use on the construction site. As a recycling mobile, the truck processes drilling mud directly on site and is sustainable in three ways: the process water for the HDD process is recycled, the amount of material to be disposed of is reduced and so are the transport journeys to landfill sites.

The recycling solution for construction companies

and municipalities

The Mudcleaner Truck is the solution for construction companies and local authorities with small to medium-sized HDD projects with a throughput of up to 180 m3 per day. As a manoeuvrable 2- or 3-axle vehicle, it is designed as a complete combination of truck and drilling rig. Profis ohne Grenzen manufactures the Mudcleaner Truck at its site in Berkheim – specially customised to the customer’s requirements. “Construction companies and local authorities therefore receive the Mudcleaner Truck in their own individual company design,” emphasises Christian Wild.

Another advantage for construction companies and local authorities is that the Mudcleaner Truck allows the construction site to be handled by just two people. As the recycling truck is particularly user-friendly, employees can operate it completely independently after just a short briefing.

New financing models

Just in time for IFAT, Max Wild GmbH is presenting new financing models for the Mudcleaner Truck: leasing and hire purchase. “We know the current economic situation and the challenges in the construction industry. Large investments in one go are difficult to realise for many companies. Leasing and hire purchase offer the necessary flexibility, but also the security that construction companies and local authorities need for their HDD projects,” emphasises Christian Wild.

With leasing periods of between 12 and 60 months, construction companies and local authorities can lease the Mudcleaner Truck risk-free and test it directly in practice for longer projects. Another financing model is hire purchase. The recycling truck is rented in fixed and predictable instalments; the rental period depends on the customer’s individual requirements. At the end of the hire period, the Mudcleaner truck automatically becomes part of the customer’s fixed assets. Particularly practical: construction companies and local authorities can include the truck in their balance sheet from the outset and depreciate it – without any major initial investment.

Three awards

Max Wild GmbH has already received three awards for its in-house innovation Mudcleaner. In 2022, the recycling revolution made it into the “100 Companies for Resource Efficiency”, a competition organised by the state of Baden-Württemberg. In 2023, the Mudcleaner won twice: VDBUM sponsorship award in the “Innovations from practice” category and first place in the Baden-Württemberg Environmental Technology Award in the “Emission reduction, processing and separation” category.

Mudcleaner truck: in use on over 200 construction

sites a year

Max Wild has its in-house developed Mudcleaner Truck in busy use: the professionals have the recycling lorry with them on an average of over 200 construction sites a year. “Our motto: as soon as a drilling rig is in use, we always have the Mudcleaner truck with us,” explains Christian Wild. The recycling lorry proves its worth in practice, as the following example shows. When laying a total of 6700 running metres of new water pipes on a construction site in Tettnang, Baden-Württemberg, the Mudcleaner Truck saved 2600 m3 of fresh water and almost 35 t of bentonite.

Who wants to know how much can be saved on different HDD drilling projects by using the Mudcleaner Truck, it is worth visiting the Max Wild website. An advantage calculator shows the individual savings potential of each construction site: https://www.maxwild.com/produkte/mudcleaner/

Booth B2, 411/510