B+W Gesellschaft für Innovative Produkte mbH

B+W Gesellschaft für Innovative Produkte mbH was founded in 1997 by Georg Buddenkotte and Christian Wiesner. After relocating in 2010, the company is now based in Bottrop, in the heart of the Ruhr area.

NALTEC® water mist system

NALTEC® water mist system

© B+W

The product range includes a wide spectrum of professional special components for silo and conveyor technology in the bulk materials handling industry. With comprehensive know-how and competent engineering, we develop individual, safe and economical solutions for our customers.

These include:

NALTEC® water mist system for:

Dedusting of bulk materials

Humidification of air and materials as well as surfaces and stockpile humidification

Cooling of air and materials

Odor elimination

Surface incrustation

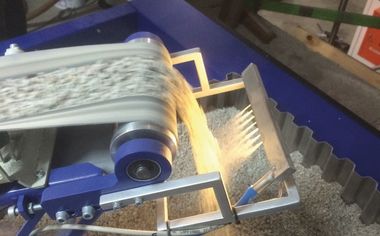

FLAER® conveyor belt scrapers for:

Cleaning conveyor belt systems

MATAKT® air cannons/air blast devices for:

Material activation in bunkers and silos

Cleaning and increasing throughput at screens

The NALTEC® water mist system is described in more detail below. Dust control is still a major problem in many areas of the bulk materials industry. The NALTEC® system developed by B+W combats this problem in a simple way. Special water nozzles form an artificial water mist that binds dust. Other areas of application include the the humidification of air in production and storage rooms as well as the cooling of room air, gas flows and materials. The system is used for odor control and surface incrustation by means of additives. The NALTEC® systems are planned and built according to individual customer wishes and requirements.

The systems can be supplied as mobile, semi-mobile or self-sufficient systems with a water tank and power generator. The NALTEC® system is also permanently installed in production facilities and can be integrated and automated into existing work processes. The high-quality NALTEC® water mist system has a high level of availability and can also be operated in winter with appropriate heating.

As a mobile spray mist unit, the NALTEC® system can be used flexibly and in a space-saving manner. All the necessary units such as the control cabinet, pump and tank as well as an adjustable fan with specially attached nozzles are combined into one compact unit.

The NALTEC® spraying system impresses with its simple technology, which optimally fulfills the most diverse applications and requirements. If required, B+W will assemble the systems completely ready for operation and the assembly department will then hand them over to the customer ready for use.

The areas of application of the water mist system are diverse. It can be used wherever fine water mist can and should be used to achieve effects. The water mist is used:

For the precipitation of industrial dusts

The extremely fine water mist generated by the NALTEC® system moistens the airborne dust and thus weighs it down. Due to the increase in weight of the dust particles, they sink quickly onto the material flow and are not carried away by the air. In most cases, a moisture increase of approx. 0.1 - 0.5 % by weight is sufficient to bind the fine dust to the material flow.

Areas of application include the bulk materials and recycling industries in particular. Here, the NALTEC® system ensures a dust-free environment at crushers, conveyor belt transfers and screens, as well as when filling silos and bunkers using conveyor belts, wheel loaders or trucks.

For odor control

The same spraying technology is used to combat organic odors, as well as amines, mercaptans, hydrogen sulphide or mixtures of these. By adding our enzymatic RESORBB® preparations, the odor molecules are quickly broken down and not masked. Odor destruction is used in waste disposal, sewage treatment plants, composting plants, etc.

For surface incrustation

A polymer is added to the water, which ensures that the surface of, for example, roadways, stockpiles, etc. becomes encrusted. The encrusted surface prevents dust plumes caused by wind drift. This protects the environment and workers from dust.

Booth B5, 541