Effective dedusting

With mobile dust binding machines, stationary permanently installed systems or indoor systems, for many years now, NEBOLEX Umwelttechnik GmbH has been a competent point of contact whenever dust becomes a challenge. At POWTECH 2016, the company is presenting a functional model for dust binding, showing the trade fair public the dust binding process in bulk solids processing on a small scale to demonstrate the principle of operation on a large scale (Fig. 1).

With the NEBOLEX Umwelttechnik dust binding system, dust binding and reduction is possible in all areas of processing. By means of special nozzles, water and compressed air are dispersed to form a mist, which depending on requirements can be introduced directly into the material or used as a horizontal or vertical curtain. With the mist formed, dust binding, air humidification or material cooling is guaranteed. To combat odours, different enzymes can be added to the water.

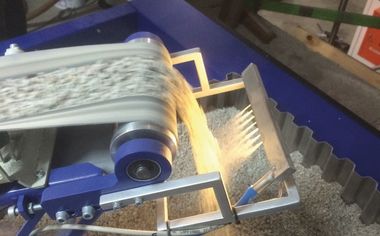

Another feature ensures trouble-free long-term use. The patented stainless steel fog bars are very robust and can be installed directly at belt conveyors and crushers (Fig. 2). They protect the integrated mist heads against any damage.

NEBOLEX dust binding systems are in permanent use 24/7 in many companies. All plant downtimes caused by excessive dust concentration or dirty or defective equipment lead to production outage lasting several hours. Seen in the long term, such stoppages cost a business more than a dust binding system that has to be maintained yearly or every six months, i.e. with scheduled maintenance intervals.

NEBOLEX Umwelttechnik GmbH works meticulously to constantly improve its dust binding systems – with the goal of offering all companies the option to reliably comply with required emission limits. And after buying a system, customers can count on good service, outside Europe too.

Hall 3 A, Stand 600