Functional model for dust binding

The exhibition model in scale 1:16

The exhibition model in scale 1:16

© NEBOLEX Umwelttechnik GmbH

The principle of dust binding works as follows: the water droplets atomized to fine water mist combine with the dust particles in the air, weigh them down and bring them to the ground. Larger drops combine with larger particles and smaller drops combine with smaller particles.

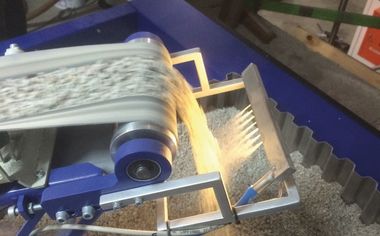

Fogging occurs in a feed hopper that is loaded with bulk material by a crane bucket. The bulk material gravel is transported further on a conveyor belt equipped with a movable belt transfer as well as a stationary belt discharge. Both positions are also fogged. The conveyor belt is also equipped with a belt weigher. Here, the fogging intensity is controlled according to the material volume. The bulk material is returned to the storage area via a second conveyor belt.

The programmable logic controller makes it possible to program different fogging activities. Thus, fogging is carried out with a time delay at different sequences. The fogging intensity can be controlled depending on the material type and material volume.

Hall B4, stand 209