What makes a reliable solution?

The unique design of the FMS BMGZ belt scales minimises the risk of damage and provides unparalleled durability

The unique design of the FMS BMGZ belt scales minimises the risk of damage and provides unparalleled durability

© FMS Force Measuring Systems

In all these scenarios, uninterrupted operating is vital. If one is forced to halt the conveyer belts unexpectedly because of a breakdown, valuable production time or stall the passage of goods are lost. Service levels will fall below what’s expected. People could even face a hefty fine for breach of contract or for safety failings. That’s why one needs a conveyer belt scale one can rely on. A small but sophisticated piece of machinery, a belt scale is fitted to a conveyer belt to continuously measure the quantity of material being carried. The scale determines the amount of material by simultaneously weighing belt load and measuring belt speed. But if it develops a fault, it can mean the conveyer belt comes to a standstill.

Design for durability

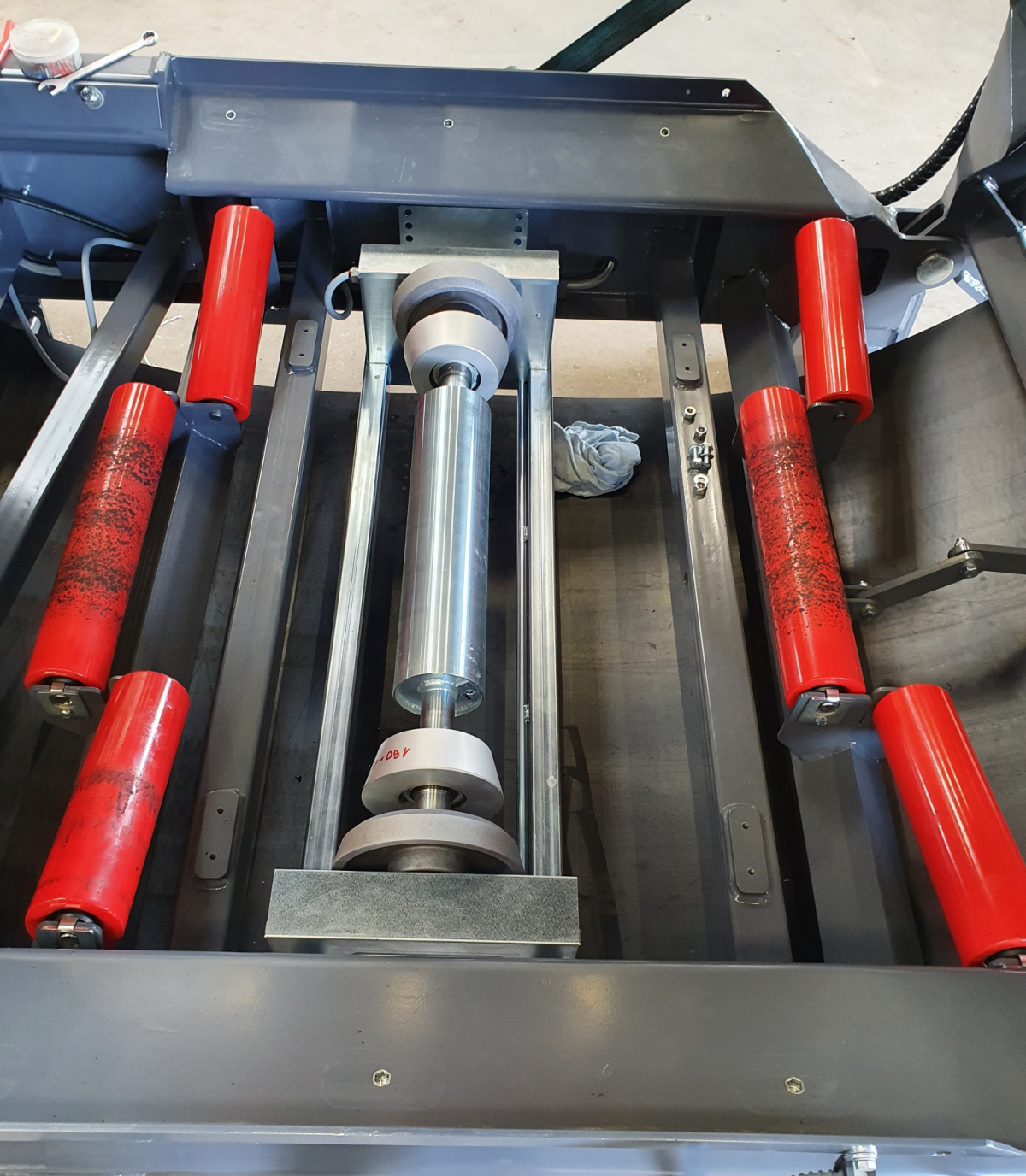

Most belt scales on the market today follow the same basic design. This is done to minimise manufacturing cost. The BMGZ is different. Unlike in competitor scales, the speed sensor is housed inside the measuring roller and there are no exposed cables. This protects the scale from damage caused by debris and the local climate – even in the harshest environments – and so helps maintain continuity of conveyer belt operation.

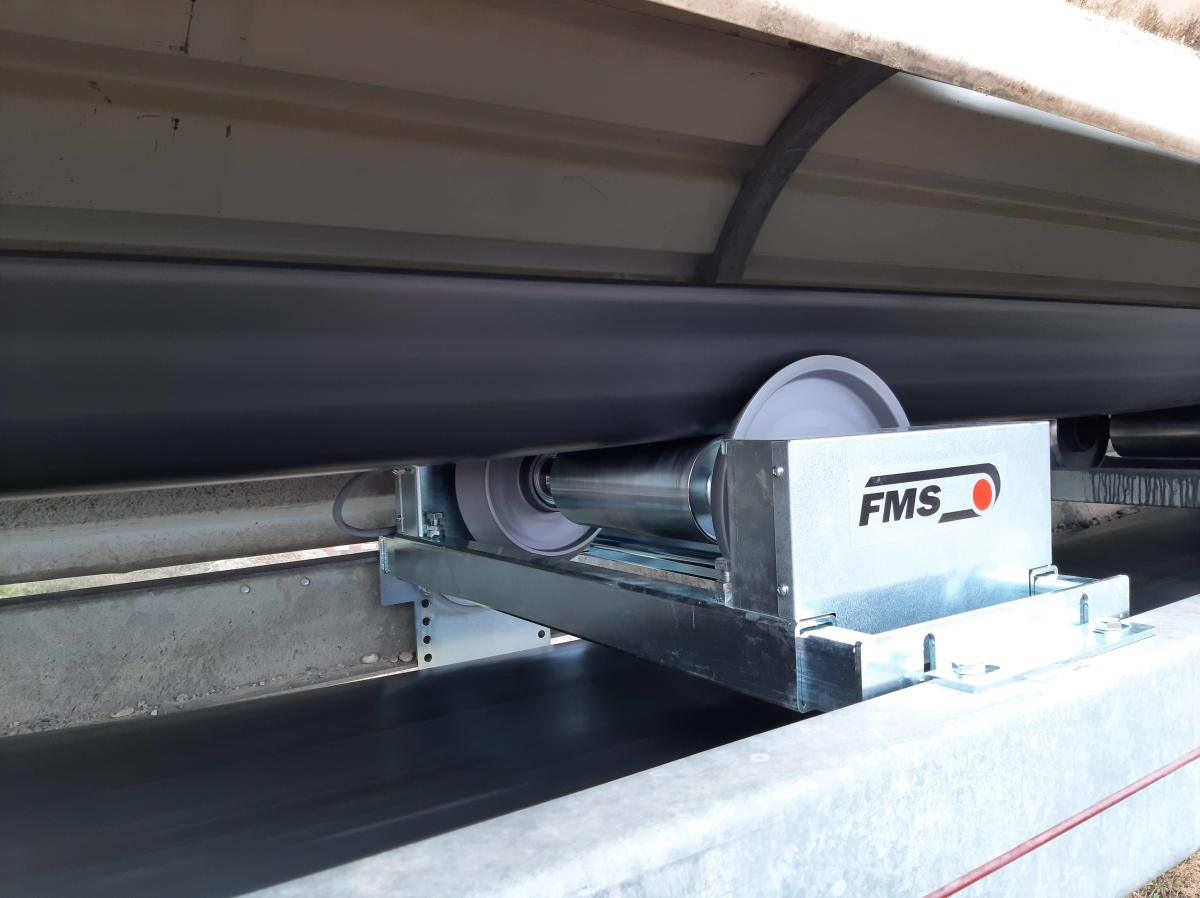

BMGZ041 measuring roller installed at an end-user facility in Holland by FMS distributor Euro Hübner Benelux B.V.

BMGZ041 measuring roller installed at an end-user facility in Holland by FMS distributor Euro Hübner Benelux B.V.

© FMS Force Measuring Systems

“Many of our scales have been in continuous use for more than 20 years with very little need for maintenance or replacement of parts,” says FMS Senior Application Engineer Björn Kjaer. “This safeguards productivity and reduces total cost of ownership.”

In fact, the BMGZ boasts an average time between servicing visits of 10 years or 40 000 operating hours. Kjaer cites an example of why reliability is so important. “I recently spoke to one of our Swiss customers whose business is providing mobile crushing services at smaller gravel pits and construction sites,” he says. “Their machines can crush up to 3400 tonnes of material each day. If a belt scale was to fail and put a machine out of action for just a day, they could lose revenue of many thousands of Swiss Francs.”

Added advantages

On top of its reliability advantage, the BMGZ scale comes in a range of roller widths and its galvanised mounting frame has slotted end plates and extendable steel legs. These features mean it can easily be fitted onto all conveyer types and sizes in stationary as well as mobile applications. There’s no need for cutting and welding as is often the case when installing other belt scales.

The BMGZ also provides unrivalled precision. Scales that do not have the BMGZ’s integrated speed sensor typically use spring-loaded lever arms to measure belt speed. As well as being more susceptible to damage, these arms are prone to losing contact with the belt in certain conditions. This can impair accuracy of measurements of speed and therefore of material flow.

Growing demand

In its home market of Switzerland, FMS has seen sales of the BMGZ series grow 70 per cent annually for the past three years. And demand is now rising fast elsewhere in Europe in settings including quarries, gravel works, mines, construction sites, cargo loading stations and roadbuilding and tunnel drilling operations.

Zürich-based FMS is also a world leader in devices for web tension measurement and web guiding used in manufacturing materials such as foil, paper, textiles, cable, wire and rope. The best-in-class load cells FMS makes for these applications are also the core technology in its BMGZ conveyer belt scales.

Due diligence: Six questions to ask any belt scales supplier:

1. How reliable is your belt scale in all conditions?

2. How many years or hours of uninterrupted operation will I get from your belt scales?

3. How often do your belt scales need to be maintained or repaired?

4. How easily can I fit your scale to my conveyer belts? Are there flexible mounting options or will it involve welding and cutting?

5. What warranty do you provide for your belt scale?

6. What is the total cost of ownership of your belt scale?