3D Laser scanning – application in plant engineering and construction

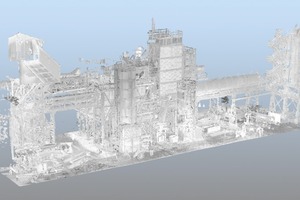

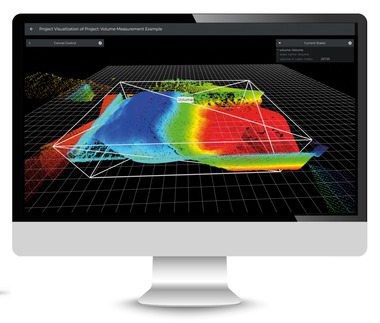

3D Laser scanning – application in plant engineering and constructionSummary: When it comes to reconstruction or revamping, very often the layout plans of buildings and site plans are not available or not up to date. Surveys are carried out by using laser measuring, metal tape measure equipment or tachymeter. All these methods are consuming time on site, besides that errors add up when measuring on the plant. This may often result in high finishing and modifying works during assembly and it can create additional quality problems and delays. Using the 3D Laser scan technology you get a three dimensional scatterplot of the site and the environmental surrounding. By the use of special software programs all single lasershots will be put together to a complete pointcloud. This pointcloud will be transferred to different CAD software formates and given to the customer as a 3D model which he can use as a base for remodelling. In addition, the design engineer can virtually walk through the plant of each 3D scan.

Starting basis and problem definition

When it comes to modifications of plants, layouts and site plans are often incomplete. Measurements are mainly taken by laser distance measuring instruments, metal tape measuring equipment or tachymeters. The on-site measuring prove to be time-consuming and major inaccuracies occur due to the addition of errors in measuring, when several measurements are taken in succession or over several plant levels. This often results in high finishing and modifying work during assembly, accompanied by problems regarding the workmanship and possible postponements of the...