Reliable measurement process for the analysis of elongated materials

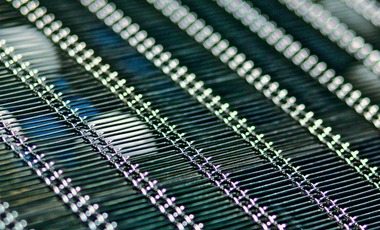

HAVER & BOECKER developed the CPA CONVEYOR process especially for the analysis of elongated materials (Fig.). The material specimen is fed via a metering channel from where it passes onto a higher speed conveyor belt. The resulting difference in speed separates the particles and brings them into stable orientation (maximum length to maximum width) before they are digitally imaged. HAVER CPA measuring instruments are based on digital image processing. A high-resolution digital line scan camera scans the particles in free-falling bulk materials against the background of an LED lighting array with a recording frequency of up to 28 000 line scans per second. The scanned lines are combined by the CPA to form an endless data record and the shadow projections of the particles are evaluated in real time parallel to the analysis process (HAVER REAL TIME). Up to 10 000 particles can be scanned and analysed every second. In addition, the HAVER REAL TIME function also enables all CPA units to be used as particle counters.

HAVER & BOECKER,

Oelde (D), Tel.: +49 2522 30-0,

www.diedrahtweber.com