HAVER & BOECKER OHG

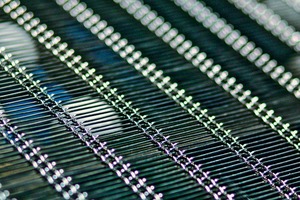

HAVER industrial screens – Square and

rectangular wire mesh cloth

From quarries, sand and gravel plants to crude oil production, from paint and powder coating manufacturers to chemical and pharmaceutical companies to the food industry – industrial screens from HAVER & BOECKER are used in almost all areas of application. The product range includes screening media for all types of screening machines with mesh sizes from 0.025 mm to over 100 mm. The materials used in addition to HAVER NIA® spring steel are various stainless steels which, in addition to optimal function, also guarantee maximum stability and longevity. All industrial screens are supplied as rolls, blanks or pre-assembled as required, equipped with various edge designs and clamping edge types or pre-tensioned on frames, according to ISO 14 315 and ISO 9044 standards.

Whenever precise cut sizes for loose materials are required or whenever long particles need to be screened, it is essential to use rectangular opening mesh (Fig. 1). When working with round or cubic type particles, a rectangular or long opening mesh is the best option.

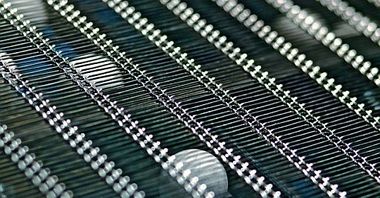

Ultrasonic screens in all variations – Safety in critical areas as well

In combination of high-precision metal wire cloth with ultrasonic technology HAVER & BOECKER provides custom-made ultrasonic screening systems with innovative frequency variation. This type of screening systems provides for more efficient screening because it improves screen throughput, helps to break down agglomerates, reduces the amount of oversize particles and ensures a long-term cleaning effect (Fig. 2). Ultrasonic screening solutions by HAVER & BOECKER can be used for cut sizes of approx. 1000 µm to 25 µm. Existing screening units with pre-tensioned screen frames can be retrofitted with this innovative technology.

//www.haverboecker.com" target="_blank" >www.haverboecker.com:www.haverboecker.com

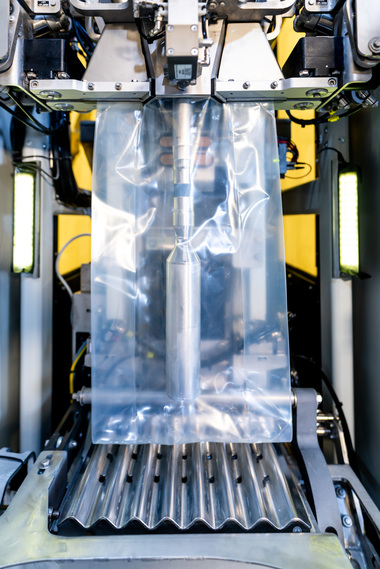

Ultrasonic screening machine system for increased throughput

HAVER NIAGARA, specialist in mineral processing technology, presents a new screening machine system using ultrasound technology. The HAVER U-CLASS® has an innovative frequency variation as well as a new solution for material transport on the screening machine (Fig. 3). Screening systems of this type provide more efficient screening by improving screening flow of material, helping to dissolve agglomerates, reducing miscibility and ensuring permanent cleaning of the screen. The energy requirement is about 30 watts per ton of feed material. Conventional screening technology is 30 to 50 times higher in comparison.

With the HAVER U-CLASS® separating cuts in the range of approx. 25 μm to 1000 μm can be realized. This innovative technology can also retrofit existing screening plants with pre-tensioned screen sections.

//www.haverniagara.com" target="_blank" >www.haverniagara.com:www.haverniagara.com

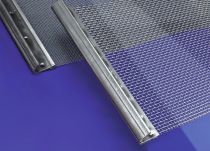

FLEX-MAT High Vibration Wire Screen –

Industrial screens for difficult-to-screen bulk materials

FLEX-MAT® High Vibration Wire Screens set the standard in lowering cost of production per ton by dramatically increasing throughput and wear life while eliminating blinding and pegging. Their distinctive lime-green polyurethane strips bond independent OptimumWire® wires – the industry‘s longest-lasting – which vibrate at high frequencies to accelerate the stratification process.

FLEX-MAT® High Vibration Wire Screens are available for ultra-fine products with a cut size of up to 0.5 mm as well as for coarser materials with cut sizes of up to 100 mm (Fig. 4). They can be used on end- and side-tensioned screening machines and on all common modular screen decks. The polyurethane strips are custom-placed to match the position of the cross bars in the customer‘s machine.

//www.majorflexmat.com" target="_blank" >www.majorflexmat.com:www.majorflexmat.com

The new Generation of dynamic Image analysis (DIA)

The HAVER CPA 2-1 laboratory device for the photo-optical analysis of particle size and shape of dry, non-agglomerated loose particles from HAVER & BOECKER has been revamped to include new technological developments. In addition to the proven strengths of the computer-supported analysis unit (among them low investment costs, GigE camera interface and optimum reproducibility with short measurement times), the measurement range has been expanded and extends from 0.020 – 30 mm. Moreover, because of the improved measurement quality, analyses are now more precise and comprehensive (Fig. 5).

An important and decisive detail for optimizing the work process and measurement quality of the HAVER CPA 2-1 analysis device is also the continuously developed software. The latest Windows and operating standards with full support for Windows 10 go without saying. Furthermore, offered are many new characteristic value options and optimized features such as automatic hopper heights, ultrasound and pre-drying.

Simplified recording of sieve data using evaluation software

With help of the Data Matrix Code (DMC) and the scanner sieve details can automatically be imported into the sieve file of the HAVER CSA (Computerized Sieve Analysis) software (Fig. 6). The scanning function enables to create and choose a sieve set. With help of the scanning function you also check if the correct sieves are in the right order for the sieving process. Two packages are available: The full version HAVER CSA EXPERT with Scanner and the HAVER CSA UPGRADE to EXPERT with manual scanner. The Data Matrix Code may be laser-etched onto existing test sieves that have stainless steel frames.

//www.haver-partikelanalyse.com" target="_blank" >www.haver-partikelanalyse.com:www.haver-partikelanalyse.com