HAVER & BOECKER OHG

AT: Give us a catchword that in your opinion best characterizes the SOLIDS 2015

Michael Stichling:

● “Your local partner” - this applies to both the fair and Haver & Boecker as local partners

● Locally

● Home

AT: What are the novelties or products, respectively, you will present at the SOLIDS 2015?

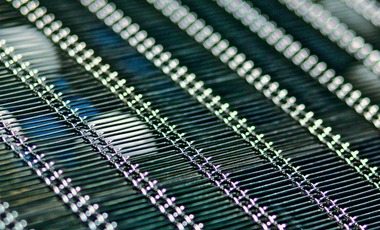

Michael Stichling: When it comes to screen media for production machines, this year’s focus is on the products and services of our new subsidiary Major Wire, which was completely taken over by Haver & Boecker at the beginning of 2015. The high performance and self cleaning Flex-Mat 3 screens, but also the corresponding services for an optimum operation of screening machines made Major Wire the market leader in North Amercia. Our customers benefit from lower production costs and higher profits. Now we want to pass on this experience to the European operators. Flex-Mat 3 screens are available for side- and endtensioned screen decks as well as for all common modular systems.

As regards the sieving analysis, Haver & Boecker will present the new generation of laboratory screening machines, type HAVER EML.

The HAVER EML 200 Premium offers a pleasing innovation – it is much more silent than the previous model. It enables pleasant working conditions in the laboratory environment with a strong performance. In addition, the damping system was revised. The transmission of the vibrations to the bottom is greatly reduced due to an improved damping system. The particularly large display ensures clarity and makes the machine intuitively operable.

As regards wet screening, the HAVER EML 200 Remote with proven external control unit is used. It can be installed flexibly at the workplace. The operation and design of the cover were improved. The full cone nozzle is elegantly integrated into the cover. The cover including inspection glass offers the usual view of the material being screened during screening. Also in this case the particularly large display is used.

In addition to the Premium there will also be the HAVER EML Pure. The new analysis screening machine offers complete clarity regarding the serviceability. In addition to the amplitude graduation for coarse and fine, no further adjustments are needed to start screening. The new HAVER EML Pure is excellently suitable as basic model for standard analyses.

The well-known product series HAVER CPA (Computerized Particle Analysis) 2-1 of the new generation is combined with the autosampler HAVER AS 6. The thorough combination of the dynamic optical particle measurement and the automatic sample feed can extend the measuring capacities, e.g. of a single-shift test laboratory, by up to 24 automatic measurements. The automatic sample identification operates completely automatically after filling the buckets and it records all results. The measured data, the Internet release provided, can be seen at any time and from any point. Even further analyses are possible at any location.

AT: What is the special feature of the SOLIDS 2015?

Michael Stichling: The SOLIDS has been established as an alternative to major fairs in the last few years. The expert audience makes it possible for us to have constructive discussions with operators and decision makers. It is even more interesting for us because the majority of the visitors comes from the surrounding geographic area.

AT: How do you assess the further development of your business field?

Michael Stichling: The screening of bulk solids will become more and more important for our customers. High-quality products can be made with the same raw material by optimizing the screening process, thus improving the operating result of our customers. Besides the choosing the best screening machine for a certain application, the selection and correct use of the screen media will become more and more important. We will support our customers even more intensively to achieve the best results with their process.

Hall 4 - Stand A 04