Saving costs with manuflex SW deflector

Consistently high cleaning results even with progressive wear on conveyor belt and deflector – such a deflector provides long service live and high cost efficiency (Fig. 1). These are exactly the results delivered by the new manuflex SW from Stricker.

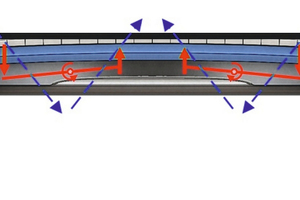

The linchpin of the manuflex SW is its patented system of active curvature with the independent adaptation to the degree of wear on belt and deflector. As a rule, the progressive wear in the center of the belt results in decreasing contact pressure. This is counterproductive, mainly because most of the residues of the materials to be conveyed adhere precisely in the middle of the belt, where the cleaning efficiency should actually be highest. Exactly this requirement is fulfilled by the manuflex SW, which automatically diverts the external forces to the center of the belt. A self-regulating lever-system is integrated in the deflector bars. Supported by the curved substructure this ensures an active curvature of the central area of the deflector bar. The latter independently adapts to the respective degree of wear on the central belt area and the deflector, and actively compensates for it. As a result, the deflector cleans with constant contact pressure for a very long period, independent of the degree of wear. Here, the cleaning performance is the highest, where it is needed most, i.e. in the center of the belt (Fig. 2).

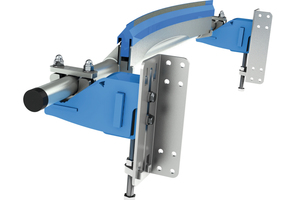

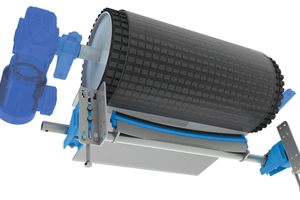

The manuflex SW provides cost benefits on several levels. The high cleaning effect enables optimum use of the transported material, and the long service life of deflector and belt ensures high endurance. Moreover, the principle of self-regulation results in low maintenance of the deflector. And the deflector bar, the only wear part of the deflector, needs to be replaced less frequently than in conventional deflectors. Moreover, the manuflex SW can score even in other fields. Its curved shape enables the smooth running of belt and deflector and minimizes the occurrence of rattling and vibrations. This contributes significantly to the reduction of the noise pollution in the transfer area and is of great value to the operation site, which is often highly exposed to noise (Fig. 3).

The voestalpine Stahl GmbH in Austria can confirm that the manuflex SW has already proven its worth in practice (Fig. 4). Provided by the service partner WANGGO Gummitechnik, the deflector is used in various plants with belt widths of 650 to 1000 mm at the Linz facility where excellent results tell their own tale. The manuflex SW also successfully passed the long-term test in a particularly demanding conveyor system, which was scientifically supervised by the AC²T (Austrian university excellence center for tribology).

//www.stricker.ms" target="_blank" >www.stricker.ms:www.stricker.ms