SOLIDS 2022 trade fair – Flexco Europe to present solutions to increase productivity for conveyor belt systems

The SOLIDS trade fair, which will take place in Dortmund on June 22 and 23, is the most important trade fair for granulate, powder & bulk solids technologies – and Flexco Europe will also be there. The specialist company will show how problems such as belt misalignment or material loss can be eliminated and avoided in the long term. At Booth A02-4, visitors will see trendsetting solutions that enable operators to increase the productivity of their plants and reduce the costs for maintenance, new conveyor belts and installation.

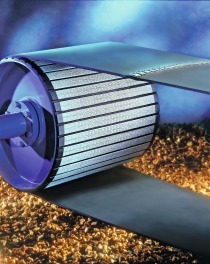

The PTEZ belt trainer is suitable for light to heavy applications and for reversible belts

The PTEZ belt trainer is suitable for light to heavy applications and for reversible belts

© Flexco Europe GmbH

Flexco Europe will also be showcasing the PTEZ belt trainer, which is suitable for light to heavy applications and for reversible belts up to 2100 mm wide. Conveyor system operators can also use the PTEZ for belts with worn or damaged edges. The system is fast and easy to install thanks to the simple design of its brackets and components. All the versions of the belt guide roller (from the standard model onward) are coated with polyurethane, but users can also opt for an economical roller coating made of rubber instead of polyurethane (PU).

Flexco offers various skirting systems to avoid loss of material in belt transfer areas in coal mines, steel plants and wood processing facilities. Fastening elements combined with a seal like this effectively insulate the bulk material without damaging the belt’s cover. This enables operators to easily reduce dust generation and increase material throughput at the same time. Flexco Europe also supplies skirt clamps for a wide range of load levels. The clamps such as the Flex-Lok series, which the specialist company designs individually for each customer are very easy to install. This makes them suitable for a wide range of conveyor belt systems – even for large and heavy bulk material transfer applications. The Dortmund trade fair will see Flexco Europe show a new variant made of PU and visitors to the Flexco booth can see the advantages of this up close.

Flexco Europe is well aware that things can get hot on conveyor belts – and the company will also be showcasing the deep-red Ultra High-Temp ConShear cleaner blades for the precleaners of the EZP1 and MSP series at the SOLIDS. Both versions feature simple installation, fast maintenance and outstanding cleaning results. Operators have access to five different PU blades for each of the two ConShear versions. Thanks to the Ultra High-Temp cleaner blade, the precleaners work very reliably, even at temperature peaks of up to 230 °C. Conveyor belts can be exposed to such high temperatures when transporting coal, clinker or cement, for instance. The precleaners are characterized by their high degree of durability for all applications, so operators have to change them less frequently than comparable competitive products – and that has a significant impact on downtimes and material costs.

Hall 4, Stand A02