New gravel plant in Farvagny/Switzerland

Challenges and objectives in design and realization

The first task was to calculate the area needed for the plant as well as the general dimensions of the site and the facilities. It was also important to guarantee the ideal transport route and access for vehicles. It was a logical step to adopt the concept of installations that JPF and ASE Technik AG had already completed in 2010 at a new gravel plant in Grandvillard near Bulle, also in the canton of Fribourg/Switzerland.

But as we all know – every construction project comes with its own particular considerations. The quality of the gravel in Farvagny, Grands-Champs differs widely from that in Grandvillard. For this reason, the washing processes and water recycling were considered in depth. Back in 2013, the first meetings and discussions were held to define the optimum process engineering for the new washing station.

The gravel plant in Farvagny is expected to operate over a lifetime lasting at least 25 years. For that reason, it was very important to automate the processes for the new plant as well as saving water and energy. The client JPF liked the concept proposed by ASE Technik AG. This was the starting signal for the detail design of the plant. When the construction permit was granted in December 2015, preparatory work could start immediately.

ASE Technik AG was granted a general planning mandate. This sort of contract offers particular advantages for all parties involved. The general planner stewards the client from the beginning of the project to the end. Together with the client’s project team, all the work for the new plant is planned and coordinated. This results in perfect interaction of the teams working in close cooperation.

First task was to complete the planning. The general planner shows the client the optimum solution. Then the project is defined from the design to commissioning according to a project workflow plan. The working and operating reliability is safeguarded by ASE and equally the final product quality. Here continuous and transparent cost monitoring is guaranteed.

Advantages in purchasing with the general planning mandate

As general planner, ASE supported the client in the procurement of all machines. Thanks to neutral tendering, the most suitable machines could be selected at the best price. The procedure is also interesting for the machine suppliers as these, thanks to the general planner, don’t have any costs or effort with project processing. Neutrality is preserved as ASE as the general planner does not generally take any commission from the machine suppliers.

The maxim for the project: Any machine that we don’t need is a good machine. The only condition on the side of the general planner: ASE Technik is contracted with the engineering, project management and supervision of the installation and is entitled to offer the conveying systems as well as the steel and sheet metal construction as a supplier. However, always in compliance with the client’s quality standards. And transparent cost accounting as well as competitive prices were always guaranteed.

A model for the future

The construction in Farvagny is a model for the future. That is confirmed too by Laurent Pasquier, Managing Director of JPF Gravières SA: “The new gravel plant optimally meets all specifications. Thanks to the energy-efficient machines and the new photovoltaic system, our gravel plant is also environmentally friendly.” And Michel Kleisli, Managing Director of ASE Technik AG, explained: “We have a team available with whom we can realize planning, design, fabrication, assembly and commissioning.” And further: “By developing and realizing a general plan together with our customer, we secure the best preconditions for successful cooperation.”

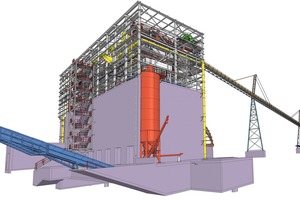

The most important specifications of the client JPF was maximized storage of finished products in concrete silos and fully automatic loading. The layout of the gravel plant was therefore designed in a straight line and with right angles – the perfect basis for optimum process engineering and overview of the plant.

The gravel plant in Farvagny is divided into different plant sections. Here an overview of the equipment:

Interim storage of the raw material with two conveyor lines for feeding the plant and loading of the raw material

Plant feed

Round gravel processing with washing system

Natural sand processing

Chippings crusher

Crushed sand and chipping sizing

Chippings facility

Metering equipment with lorry loading station

The new gravel plant in Farvagny impresses with systematic environmental friendliness: The entire roof of the processing plant and the associated office building is covered with a photovoltaic system designed according to state-of-the-art standards. In this way, a large part of the power requirement is covered, which has an extremely positive influence on energy costs.