VHV Anlagenbau GmbH

The exhibition stand of VHV Anlagenbau GmbH appears in a completely new light. Where formerly flying balls and running plants of the latest material handling technology were presented, this time we have the monitors “run”. With animated pictures and movies the visitors are introduced to the detailed plant planning and design.

Material handling must be adapted to the building conditions and therefore modularity is a must. Tailored solutions of an extremely space-saving design and clean production facilities of the customers are ensured by the innovative material handling equipment from VHV Anlagenbau. VHV Anlagenbau not only supplies conveying equipment, but also provides three-dimensional planning and design for the corresponding plants. Thus, critical space conditions can be used optimally and the complex line courses in the plant can clearly be shown.

Many years of experience as well as exact design and calculations of the required conveying parameters ensure trouble-free operation. Already during the planning phase of the plant or factory, the customers are accompanied and, consequently, extremely efficient concepts are developed. Amongst other things, VHV Anlagenbau offer the double belt conveyor as a space-saving alternative to standard belt conveyors for steep-angle conveying.

In addition to a low expenditure for cleaning and maintenance, the double belt conveyor of the new generation ensures continuous, vertical conveying with a low drive power. When using smooth belts, the material can be conveyed very steeply, vertically and even up to a height of 30 m. The double belt conveyor can be used for particle sizes of approx. 1 to 100 mm. The double belt conveyor from VHV ensures homogeneous conveying without residues or mixing of the most different materials to be conveyed, if they are handled one after the other. Compared to side-wall, ribbed and pocket belt conveyors, the expenditure for maintenance and cleaning can be considerably reduced due to effective scraping and cleaning systems, since the VHV double belt conveyors are equipped with the usual smooth belts. The Swiss recycling company ARBA in Altdorf/Switzerland, has also decided to purchase the trouble-free and energy-efficient conveying system.

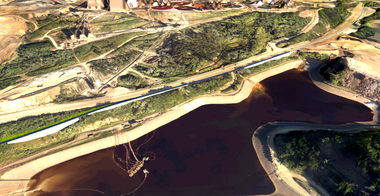

In Switzerland VHV is represented by the Lucerne-based company ASE Technik AG, which will also support us at the bauma as a competent partner. As a partner of VHV, the company ASE Technik planned, designed and erected the new plants of the gravel works JPF Gravieres Sa Bulle in Switzerland combining the latest extraction and processing technologies. The gravel works JPF represents the state of the art as regards rock extraction, processing and loading equipment. A comprehensive know-how of conveying engineering was required to get to the various production facilities, from the feed point including primary crushing plant via intermediate stores up to the preparation of round gravel and natural sand, and further via the washing plant up to the storage hall for crushed sand and chippings including truck loading station. According to the plant concept, the material is not moved by any construction machinery and equipment from the feed silo up to the truck loading station. All processing steps are carried out directly via the innovative, galvanized belt conveyor systems from VHV Anlagenbau. Thus, an economic operation is ensured.

Hall B2; Stand 224