New Kubria® cone crusher for Tiefensteiner Granitwerk GmbH

ThyssenKrupp’s Industrial Solutions business unit is one of the international leaders in the design, engineering and servicing of industrial installations and systems. As a premier manufacturer of crushers for the cement, minerals and mining industries, the crushing equipment unit at the Münsterland site is supplying a Kubria® cone crusher for the comminution of granite, porphyroid granite and gneiss to Tiefensteiner Granitwerk GmbH, a company based in Laufenburg.

Following 28 years of continuous service in the toughest conditions, the existing crusher is being replaced with a modern machine. It was particularly important to the owner that the company use the proven technology supplied by ThyssenKrupp again.

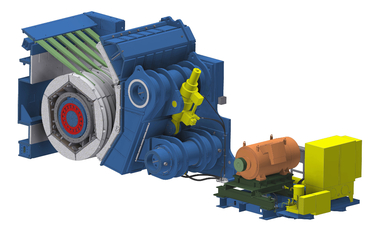

For this reason, a Kubria® F/M 90 has again been selected for crushing different feed sizes from 8-16 mm to 32-100 mm (Fig.). Depending on the crushing gap setting, products in the sizes 0-5 mm or 0-16 mm can be produced. The crusher is supplied with the proven Kubriamatic control system. This enables adjustment of the crushing gap even during operation. On the ingress of foreign matter, the main shaft is lowered automatically so that the foreign particles can pass through the crushing chamber usually without causing any damage. To cope with the high hardness and toughness of the raw material feed, the crusher shaft is equipped with a hydrostatic bearing, which works largely wear-free at very high crushing pressures. Thanks to the proven cyclo-palloid toothing of the drive bevel gears, despite the quiet, low-wear operation, higher drive power can be transmitted than with the old crusher, so that a more powerful motor can be used. Access to all heavy replaceable parts from the top of the crusher makes it very maintenance friendly.

$(LEhttp://