thyssenkrupp equips Tiefensteiner granite works with Kubria® cone crushers

Since the 1980s, various cone crushers have been used in the Tiefenstein granite works (Fig. 1). After around 30 years of continuous operation under the toughest conditions, the crushers now had to be modernized in order to meet the high quality requirements in the future and to be able to produce the necessary quantities of individual grains. In the past, especially the Kubria® cone crusher used in the fourth crushing stage had proved its worth in crushing. For this reason the company again relied on the proven technology of thyssenkrupp for modernization.

Higher capacity and availability with Kubria® cone crushers

Work began with the replacement of the Kubria® F/M 90 cone crusher installed by thyssenkrupp in 1986. The crusher is the fourth crushing stage in the Tiefenstein granite works and produces high-grade crushed sand (0/2 mm) as well as various grit fractions (up to 16/20 mm). The crusher was replaced in 2016 and initiated the modernization of the entire plant.

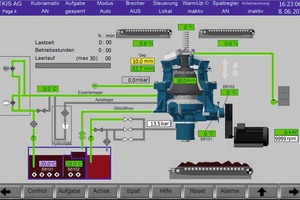

The new Kubria® F/M 90 (Fig. 2) is equipped with the proven Kubriamatik control system (Fig. 3), monitoring all important operating data such as gap width, power and pressure as well as temperatures and oil flow. Other important operating values such as operating and load hours as well as the number of pressure and power peaks are available on demand. The crushing gap is automatically controlled depending on adjustable power and pressure limits. In this way, the degree of wear of the crushing tools can also be conveniently checked and corrected. This results in a constant product at all times. If foreign bodies penetrate, the crushing cone is automatically lowered so that the foreign body can pass through the crushing chamber. The operating data can be queried via mobile radio or satellite and analysed by the supplier, for example, via the Teleservice offered. Due to the insufficient mobile phone connection in the remote plant area, a satellite system was installed in the Tiefenstein granite works.

Due to the great hardness and toughness of the raw material, the crusher axle was equipped with a hydrostatic axial bearing. This operates largely wear-free even at very high operating pressures. Due to the cyclo-palloid gearing used to drive the crusher axle, it is possible to transmit higher drive power than with the old crusher while running quietly and with low wear, so that a more powerful motor could be used. As all heavy components of the new crusher are accessible from above, it is very easy to maintain.

In 2017, another Kubria® F/M 90 cone crusher was commissioned for use in the tertiary crushing stage. The starting material with lump sizes between 70 and 120 mm is crushed to a grain size of less than 32 mm (80 %). This crusher was also equipped with hydrostatic axial bearings and the intelligent Kubriamatik control system. Finally, a Kubria® G 90 was commissioned in 2019 in the new secondary crushing stage (Fig. 4). The “G” in the product name stands for coarse crushing. In contrast to the Kubria® F/M (F/M = fine and medium crushing) type, the crusher has a steeper crushing cone. This allows coarser material to be processed. The Kubria® G 90 is therefore particularly suitable for use in the second crushing stage. In the Tiefenstein granite works it processes a pre-screened feed material with edge lengths of 50 – 270 mm into a product with a proportion of 80 % smaller than 40 mm.

In addition to replacing the crusher, extensive conversion measures were carried out on the entire plant. For example, an old, underground material extractor was upgraded, which transports the feed material to the secondary crusher via a likewise new conveyor system. This enabled the material flow in the plant to be optimised and a constant and largely automated production to be achieved.