Maximising plant productivity with turnkey solution

“We have been working with MATSA for 12 years and our service team has built a solid partnership with them. We opened a service site close to MATSA and employed a full-time Service Engineer on site to provide adequate support,” states Seda Kahraman, Regional Process Engineer Manager for Weir Minerals. “Working on this particular project was both very challenging and very rewarding. They needed to increase their grinding circuit capacity from 275 t/h to 307 t/h, whilst reducing the quantity of ultrafines in the final overflow of the second hydrocyclone cluster.”

Antonio Gamiz, Plant Technical Director states: “To maximise our plant productivity we needed a Cavex hydrocyclone cluster that was specifically designed to our application. This was achieved without an extension of the plant area and with minimal capital expenditure.” First, Weir Minerals created a simulation of the entire primary and secondary grinding circuit. This enabled them to visualise how the process should be running, and the most appropriate way to deliver this.

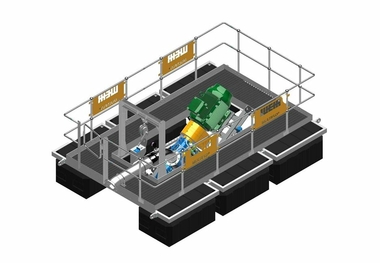

Following the simulation, the best operating conditions were calculated to support the required capacity increase and elimination of slimes. This included the ball mills, mill liners and hydrocyclones. Using 3D laser scanner technology, the team at Weir Minerals developed a suitable layout for the equipment, including modification and steel structures.

To deliver the solutions MATSA required, Weir Minerals replaced the primary hydrocyclone cluster, as well as the spare parts on the secondary hydrocyclone cluster; redesigned the steel structure and walkways; installed new hydrocyclone feed pumps and piping configurations, installing and commissioning the entire project.

The modification to the steelwork and piping, as well as the assembly of the new three-way Cavex® 650CVX hydrocyclone cluster were completed in less than four days without any production interruptions. Upon analysing samples from various points in the grinding circuit, it was confirmed that the feed capacity had successfully increased to 300 – 307 t/h. “In addition to the desired increase in grinding capacity, we also improved circulating load in the primary ball mill and restored the feed pressure to the Cavex hydrocyclones to 85 kPa. We are thrilled that MATSA achieved payback in just three days due to the increase in production by 500 t/d, and achieved additional revenue of 2751 €/h”, concludes Seda Kahraman.