Knowing how

Dear readers,

Measurements alone often do not provide a satisfactory answer to a problem as long as one does not know how and under which conditions the measurements were made and how the measured values were interpreted or converted. We can therefore only trust certain measurement results if we know under which conditions and with which technical specifications they were determined. This is also the case with level measurement. The article ” Radiometric measurements – accuracy, repeatability and errors” (from p. 36) deals exactly with these points in level measurement and explains how to obtain reliable results despite certain external influences.

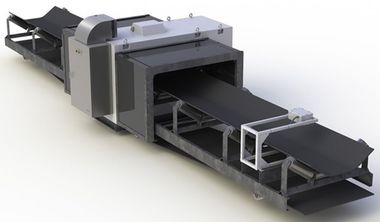

Fine mineral powders often cannot be processed in their original form because handling them in technical processes is extremely difficult. One solution is to agglomerate the fine particles into pellets or granulates. This processing step is found, for example, in the fertilizer industry, in ore processing or in the processing of ashes. In the article “Built-up agglomeration – When to use a mixer and when to use a disk pelletizer or pelletizing drum?” starting on page 48, the suitable preparation technology aspects are presented and discussed and the corresponding processes are examined in more detail.

Many other contributions on the topics of ore processing, dewatering & drying and crushing & wear protection offer you an insight into new products and present current projects.

I wish you an interesting time with this issue