Using real time elemental analysis of conveyed ore flows

Summary: Real time analysis of ore quality between the mine and mill provides major benefits to copper mining and processing operations. Prompt gamma neutron activation analysis (PGNAA) is a proven technique that has been successfully applied for real time conveyed flow multi-elemental measurement. The advantage of PGNAA is that it measures through the full conveyed cross section continuously and provides representative element measurement without the need to constantly sample coarse (primary crushed) conveyed flows. High specification PGNAA analyzers enable accurate measurement over time increments as short as 30 s. Elements such as copper can be measured to a precision of 0.02 % copper which is sufficient for high confidence in decisions for bulk flow diversion. Increments of 8 tonnes are being diverted through a bulk ore sorting application to remove batches of waste from mill feed as well as divert material to different stockpiles based on ore quality. Longer measurement increments of 2 to 5 min are suitable for blending control of ores to reduce feed quality variability and to control average ore quality within a target range. Feed blends can be adjusted as frequently as required but typically multiple measurement increments are composited to produce a rolling average ore quality. The paper details two case studies where analyzers have been successfully used to measure conveyed flows for blending and bulk diversion applications. The real time measurements of ore composition are also used for ore reconciliation, in metal accounting and providing process operators with advance warning of ore quality changes that may affect grinding performance and cause process upsets. Real time ore quality measurement has proven beneficial in improving copper processing performance through better utilising plant capacity in a leaching operation, optimising ore feed quality, and reducing unnecessary processing of waste.

Representative real time elemental analysis of conveyed ore quality using fully penetrative technologies has been available to the minerals industry since the 1990s. The Prompt Gamma Neutron Activation Analysis (PGNAA) technique was developed into a conveyed material analyser and soon adopted by the cement and coal industries which recognised the benefits in real time quality management. These commodities were ideally suited to this measurement technique as operations generally involved conveying bulk material prior to processing. Measured quality was used to divert material to different destinations or used to control blending for improved quality consistency. Uptake in the minerals industry, however, has been slow until the last ten years, and particularly until the mid-2010s.

This paper discusses the PGNAA technique and why it is well suited to copper mining and processing operations. Two case studies are discussed which use the technology in very different applications; the first in a blending and feed forward application and the second in a bulk diversion, or bulk sorting, application. The differences between the applications are discussed in terms of analyser configuration as well as the operational benefits delivered to each site. Measurements can also be used for additional applications and process improvements and while not yet used in copper processing operations for some of these their potential benefits are also discussed.

Prompt gamma neutron activation analysis

The PGNAA technique relies on a source of neutrons to excite elemental nuclei in conveyed materials. Californium-252 (Cf-252) is typically used as it is the most prolific source of neutrons at suitable energy levels. Other sources of neutrons may include AmBe (Americium Beryllium) or neutron generators. These produce either far fewer neutrons or generate them at much higher energies, both of which may result in sub-optimal measurement results. The majority of PGNAA analysers installed utilise a Cf-252 source housed beneath a conveyor belt and a detection system housed above the conveyor belt. Detectors are used to measure the unique gamma energy emissions produced by each activated element over an analysis time increment. Bismuth germanium oxide (BGO) detectors are an example of a high performance detector type and high specification analysers generally contain multiple BGO detectors. Spectral responses are combined with mass flow data supplied by a belt weigher external to the PGNAA analyser and commonly a moisture analysis is provided by a nearby system. Transmission microwave-based analysers can provide reliable free moisture measurements.

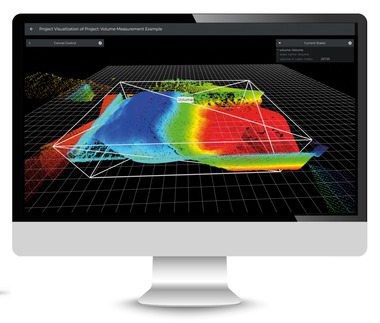

Spectral information, mass flow data and moisture data are used to calculate the elemental composition of segments of the conveyed flow so they can be reported to a plant control system in real time. High specification analysers contain relatively large Cf-252 sources, initially fifty micrograms or larger, and multiple BGO detectors in a structured array above the conveyor. They utilise advanced belt load compensation software and customised calibrations to determine tonnage weighted elemental and moisture content over time increments as frequently as each thirty seconds with good accuracy over a calibrated range. Lower specification systems may provide acceptable measurement accuracies for elements of interest over longer measurement times, potentially each 30 or 60 min, which limits the potential responsiveness of the plant to such data. Numerous papers have detailed the PGNAA technology and its applications for process control in the minerals sector generally including Kurth (2007), Kurth and Edwards (2008), Kurth (2013), Balzan, Harris, and Bauk (2017) and Patel (2014). A major benefit of PGNAA is that the technique is penetrative to over half a metre and instantaneous. Particle size, mineralogy, layering, moisture content and belt speed do not affect the analysis. Conveyed flows on belts to beyond 2.4 m wide and bed depths in excess of 0.5 m deep can be measured.

PGNAA systems are particularly useful when they are configured for a specific application. High specification systems will provide optimal performance where short measurement increments are required with good measurement accuracy for bulk diversion applications (also called bulk sorting) as selectivity is enhanced if decisions can be made on smaller increments of flow which relate to smaller tonnages. Longer measurement times can be successfully applied where blending is the main application. Compositing of measured increments provides useful smoothing, and moving averages, upon which blending decisions are made. The short term variability is still visible in the component data and blending responses are not necessarily required as each change occurs as this may contribute to wider quality fluctuations.

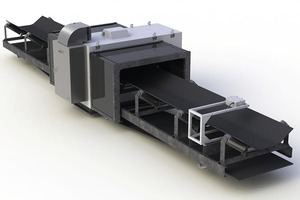

Good PGNAA analyser design should incorporate sufficient safety mechanisms to limit radiation exposure to plant and maintenance personnel during operation and down time. Technologies involving radiation require certification in jurisdictions where the equipment is to be supplied as well as detailed work instructions relating to source shipment, handling and storage. Automatic source drive options allow the Cf-252 source to be isolated within seconds of an appropriate event occurring. These may include a conveyor belt stopping, running empty, operating at below minimum belt load requirements for accurate measurement, or a power outage to the area. It may also include a manual shutdown to allow for maintenance near the unit. It is preferable that no isolation area around the analyser is required. The design in Figure 1 meets all these requirements. In addition, the source is underneath the conveyor where any impacts by conveyed rocks cannot dislodge the source.

Maintenance of systems can be reduced through designs that eliminate contact with the conveyor belt altogether. A narrow frame can fit between idlers so that the belt is supported through the tunnel area. This reduces the likelihood of conveyor downtime due to damage to the analyser or belt. Robust analyser design is also important for plant environments and long equipment life. The Cf-252 has a half-life of 2.65 years requiring an additional half-size source to be added each two and a half years to ensure ongoing neutron supply and high measurement accuracies. Source disposal is required each ten or eleven years and depleted sources are returned to the supplier for resale to other industries. Cf-252 sources are totally consumed over a twelve to fifteen year life and do not contribute to the global nuclear stockpile. Calibration maintenance is the only other operating cost of significance and this is performed six monthly to fine tune the calibration to the conveyed material which generally changes over the life of a mine as different ore zones are mined and processed.

Measurement results are transmitted directly to the plant control system and time stamped so that relevant responses to the measurements can occur at the correct time. This is particularly relevant in bulk diversion where the lag time between analysis and the diversion point is critical for accurate diversion of the target increment. A diversion gate or plough should be activated to accurately coincide with the start and finish of the conveyed increment (of typically 30 s, 1 min or 2 min). Any delays or mistiming will result in an increment including material from the preceding and/or following increment which may have a different composition. This may result in waste being kept within the ore stream or ore being rejected with waste. A suitable materials handling strategy should be developed and implemented to optimise the selection and removal of required flow increments. In ore blending the response may be less critical as ore quality is averaged over longer conveyed increments and changes made to blends will not have the same potential negative results if delayed by seconds or minutes.

Case studies

Sepon copper-gold operation

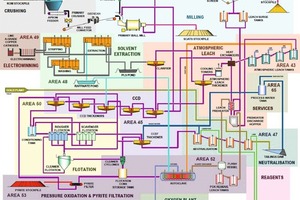

The Sepon Copper Operation in Lao P.D.R. was developed by Oxiana in 2002 and was subsequently sold to MMG and in 2018 to Chifeng Jilong Gold Mining Company. Copper resources were expected to be depleted by 2020 and only gold oxide resources remained prompting MMG, whose focus is copper, to sell the operation to a gold focussed company. A GEOSCAN-M PGNAA elemental analyser was installed in 2008 as it was recognised that the high copper feed grade variability represented a risk to plant performance if not managed effectively. Copper mineralisation occurs as supergene enriched chalcocite and oxides including malachite, azurite and cuprite. Figure 2 shows the process flowsheet and location of the analyser on the mill feed conveyor.

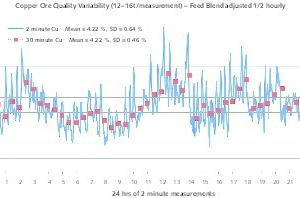

Multiple small opencast mines provide ore parcels to run of mine stockpiles. Within each stockpile there is high copper content variability and a controlled blending of the feed was deemed by the metallurgists as a requirement to maintain a consistent copper metal feed to a whole-of-ore leaching circuit. Overloading the circuit with copper metal resulted in copper losses so a control range was defined and an analyser used to monitor average feed quality over 5 min measurement increments which were tonnage weighted averaged over 30 min to review copper metal tonnes. Blend changes are made to maintain copper metal tonnes within the target range. Figure 3 is an example of data variability over a 24 hour period at Sepon.

As mining and processing advanced the proportion of acid consuming gangue increased significantly and acid consumption increased proportionally. Analyser measurements of calcium, magnesium and manganese were found useful to control Gangue Acid Consumption (GAC) and this provided major improvements in plant control. Furthermore, process operators were able to incorporate measurements of iron and sulphur to manage the pyritic material addition to the ore required for ferric leach chemistry control. The moisture content has also been incorporated into the mill feed control as it also affects acid consumption. A more detailed account of the Sepon operation and the elemental analyser application history is available in Balzan, Jolly, Harris and Bauk (2016) and Arena and McTiernan (2011).

New Afton copper-gold operation

The New Afton copper-gold operation near Kamloops in British Columbia is currently owned and operated by New Gold Inc. of Canada and is on the site of the historic Afton Mine previously operated by Teck Resources. Copper, gold and silver mineralisation is mined by block cave and sampling of mined ore has shown large variations in ore quality. The block caving process results in ore being withdrawn from draw bells over the life of the cave with intermittent waste zones and then a mixture of ore with increasing proportions of waste until the material is considered uneconomic to remove and process.

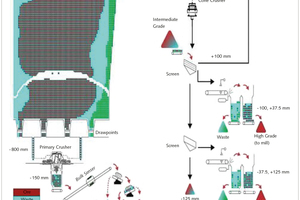

Applications of bulk and particle ore sorting were evaluated and detailed in Nadolski, Klein, Samuels, Hart, and Elmo (2018) and Nadolski, Samuels, Klein, and Hart (2018). Review of extensive sampling each 300 tonnes of extracted material from each draw bell indicated the potential to remove approximately ten percent of the mined tonnes using a 0.3% copper cut-off with the loss of only 1.5% of the copper metal. The mill feed grade was expected to increase from approximately 1.1% copper to 1.2% copper as a result. The use of bulk analysis utilising PGNAA on conveyed flow from the underground crusher to the surface crushed ore stockpile was recommended in these evaluations. Increments of waste could be determined from bulk measurements of the conveyed flow and diverted prior to the crushed ore stockpile and removed. Lower quality material could be upgraded by multi-stage particle sorting. Higher quality ore could continue to the crushed ore stockpile for processing in the concentrator. Figure 4 shows the proposed bulk and particle ore sorting stages proposed by Nadolski et al. (2018a). The presence of picrite in the waste zone vertically parallel to the block cave is of particular concern due to its negative affect on copper recovery if processed with ore. Elements were identified which help identify the presence of picrite. Gold is highly associated with the copper sulphides and can be calculated from copper and sulphur measurements with reasonable accuracy (RMSD of 0.15 ppm) whereas chromium and nickel are strongly associated with the picrite.

Samples from site were crushed, homogenised and representatively sub-sampled prior to laboratory analysis by site. The samples were sent for testing in the GEOSCAN-M and capabilities of the technology evaluated using various analyser configuration options to achieve the optimal balance between measurement increment and accuracy. The shortest possible time increments provide maximum selectivity in diverting the smallest tonnage increments. A 30 second measurement time was agreed for New Afton which represents approximately eight tonnes on the 1,000 tonnes per hour flow. The measurement accuracies for the critical elements over expected composition ranges as shown in Table 1 were considered by New Gold Inc. to be adequate for confidence in diversion decisions. Further explanations of the GEOSCAN-M suitability have been described for this application by Kurth and Balzan (2017) and Balzan, Harris, & Bauk (2017).

A significant advantage New Afton has over many other operations is the capacity the mine has to produce approximately 25% more tonnage than the mill can process. This is an ideal situation for bulk analysis and diversion to remove uneconomic material from the ore stream. The economics used in the original evaluation of bulk sorting used 300 tonne increments to suggest sufficient benefit to implement this. Measurement of each 50 tonnes was requested to achieve a finer resolution however eight tonne increments are expected to produce significantly greater benefits. GEOSCAN-M performance has met measurement expectations and operator’s understanding of ore variability at different scales will ensure an appropriate bulk diversion strategy is implemented.

Further benefits of elemental analysis in copper processing

The PGNAA applications in the two case studies demonstrate proven measurement performances for multiple elements used in process control decisions. More importantly the measurements are used for multiple purposes; a primary purpose which is usually the basis for analyser financial justification and secondary purposes for which economic justifications are difficult to quantify. These may include ore quality monitoring to confirm if quality meets an expectation, ore reconciliation, metal accounting, and feed forward of ore quality to downstream operations. The benefits directly linked to either blending or bulk diversion can be determined after a period of time during which the ore variability is measured and understood and the process implications studied and improvements are implemented and evaluated. Other uses of the data may have no direct economic benefit. This section discusses uses for the real time data in copper processing that have yet to be used for economic justification but in some cases the benefits are obvious.

Other mine to mill applications

Analysis in real time is used in other commodities to measure ore quality underground to help manage hoisted ore quality, particularly where multiple ore storage pockets are utilised prior to hoisting ore. This allows ore quality to be blended and controlled to a target quality. The greatest benefit in measurement early in the ore handling process is the potential to remove material that has low value and does not require additional processing, either further crushing stages or grinding and processing. This can be achieved where grade by size analysis indicates a preference for grade deportment to coarse or fine fractions lending the material to be suitable for upgrade by simple screening. Coarse and fine streams can be measured to quantify and control the outcomes of this process.

Conveyed ore is measured and stockpiled according to quality, either of the primary metal content or by its deleterious content, to improve flexibility in blending into the grinding circuit and improve quality consistency, which is known to improve process efficiency and metal recoveries. This occurs in the phosphate industry with phosphate rock where another analyser after the stockpiles controls the proportioning and ultimately the consistency entering the process. It also allows deleterious content to be well managed through appropriate blending to minimise its negative impact on the process; contamination of concentrate or reduction in primary metal recovery.

Geometallurgy

Measurement of ore flows prior to the grinding circuit can provide useful information for process control through ore characterisation and identification. Changes in ore grade alone may be useful but changes in ore type which require changes to the process strategy are also useful. The changes may include different reagents, changes in dosing rates, changes in throughput rate, or diversion to a different circuit or process due to changes in mineralogy or changes in elemental ratios such as the copper to sulphur ratio. Measurements can be used to track ore by identifying types relative to the mining areas from which they were extracted in the mine scheduling sequence.

Fingerprinting of ore types enables process operators to identify material that may be new to the process or of a quality that has been processed previously. The treatment regime may be modified if a certain ore type behaved in a certain way in the plant so that process changes can be implemented to improve recoveries from the same material the next time it is processed. Benefits in the application of machine learning, artificial intelligence and digital twin technologies are possible as these systems can identify previously unrecognised relationships between the material quality and its outcomes when processed.

A parameter not usually associated with elemental content is ore hardness or grindability where silica content or changes in silica relative to other elements may indicate a much different ore character that has significant consequences if not managed. Overloading mills can result in plant shutdowns and equipment damage as well as lost production. There may also be opportunities to increase throughput when softer ores are measured before the mill. Clay content may also be an important consideration particularly if the clay content is highly variable or its composition is variable. Sulphur is a useful element for distinguishing ore that may be better suited to processing by leaching than flotation. Sulphur content may be useful for environmental management by diverting acid generating waste conveyed from the mine to a contained destination and clean waste to aggregate and construction material by-product streams.

At mill applications

Once the ore is in the mill there is little more that can be done to improve the quality that feeds the process plant, be it flotation or leaching or beneficiation. Pebble recycle flows are an obvious bulk measurement and diversion application that has not yet been implemented in copper processing. Pebble recycling incurs additional processing costs through conveying, pebble crushers and occupying mill capacity that could be replaced by fresh ore. The economics are clear where pebbles are below cut-off grade and ore is available to replace the flow but they are recycled nonetheless. The poorer outcome occurs where pebble flows, irrespective of quality, are rejected when ore supply is plentiful. How much metal is being discarded? Pebbles are suitable for particle sorting in some cases and diversion of sub-economic pebbles to particle sorting may improve metal recovery and optimise processing costs significantly.

Concentrate applications

Concentrates produced through flotation may have variable quality including contaminants such as talc, arsenic or zinc minerals which could result in rejected shipments if not managed effectively. The PGNAA technique is equally effective on fine particles as it is on coarse material. Concentrate quality measurement can be used to bulk divert material to isolate out of specification material to be later blended in a controlled way with better quality concentrate.

PGNAA systems are extensively employed in loading operations in many industries to measure and control the quality of material placed onto trains and ships. This is the case in the coal, bauxite and iron ore sectors where bulk commodities are transported. In no cases are PGNAA measurement system used for certification of shipment quality, however, the continuous analysis and real time results provides the loading operators confidence their shipment is on specification before samples are analysed for the official certificates of analysis. These often become available after the train or ship has departed. Currently no ISO standards allow for analysers to be used in certification. The author is aware of at least one coal operation where agreements between a coal miner and a power station owner allow the analyser results to be used for payment terms as both parties contribute to the analyser maintenance and calibration incorporates external laboratory results. Measurement performance is a function of ongoing attention to calibration and consequently any certification would have stringent calibration maintenance requirements.

PGNAA can be very effectively used in smelters that blend concentrates and control additives, such as fluxing agents, through measurement of the combined flow and adjustments to the feed proportions of each material. The iron ore sector is utilising PGNAA for basicity control of sinter at steel-making operations.

Conclusions

The implementation of high specification PGNAA systems such as GEOSCAN-M has been proven to be beneficial and provide fast paybacks in multiple applications, particularly in the two case studies outlined. Whilst ore blending and bulk diversion are obvious applications of conveyed flow measurement a number of other applications are identified that have attracted strong interest within copper processing operations. Nearly all of these applications have been successfully implemented in other commodities. With declining copper ore grades and an effective limit being reached on economies of scale in processing equipment the application of intelligent solution to reduce the amount of waste processed should be strong motivator to consider such technologies. Further advantages are that processing fewer tonnes of waste will generate fewer tailings and consume less energy, crushing and grinding consumables, water, reagents and maintenance requirements. Rejecting waste material earlier in the mine to mill stages and feeding processes with not only more consistent feed but at a higher quality will improve process efficiencies, metal recoveries and productivity.

Capabilities of PGNAA in elemental measurement performance will improve with ongoing development. Measurement over 30 second increments was possible using a flexible but robust design due to persistence and innovation of calibration engineers. At the time of writing the paper, recent developments have occurred that enable more elements to be measured to lower detection levels including gold. Many copper orebodies contain strong associations between copper minerals and gold, however, some gold may not be associated with the copper or sulphides and is present in significant grades. High specification PGNAA systems are currently unique in their ability to measure elemental content of conveyed flows continuously and through the complete conveyed profile over short measurement increments.

Acknowledgments

The author wishes to thank Scantech International Pty Ltd for permission to publish and present this paper. Oxiana/MMG and New Gold Inc. are thanked for their industry-leading positions in adopting new technologies to the copper sector and their willingness to share data and to be reference sites. The copper companies currently implementing GEOSCAN-M systems in Canada, Chile, Australia, Zambia and DRC are also acknowledged for their ongoing support. Dr Luke Balzan, Technical Manager at Scantech and his team have made significant and unique developments to advance the capabilities of GEOSCAN-M in measurement of copper and related elements.

Literature

Arena, T., & McTiernan, J. (2011). On-belt analysis at Sepon Copper operation, Proceedings Metallurgical Plant Design and Operating Strategies (MetPlant 2011) 8–9 August 2011 Perth, WA, The Australasian Institute of Mining and Metallurgy, Melbourne, pp. 527–535.

Balzan, L. A., Harris, A. R., Bauk, Z. (2017). Faster Analysis: Recent advances in Geoscan on belt analysis techniques allowing for rapid real-time measurement of minerals, Proceedings of Conference of Metallurgists (COM 2017), Vancouver, Canada (in preparation).

Balzan, L. A., Jolly, T. D., Harris, A. R., & Bauk, Z. (2016). Greater use of Geoscan on-belt analysis for process control at Sepon copper operation. Proceedings of XXVIII International Mineral Processing Congress. Quebec, Canada: Canadian Institute of Mining, Metallurgy and Petroleum.

Kurth, H. (2007). Online analyser technologies for conveyed materials - timely, representative and reliable data for improved process control, Proceedings 2007 Australian Mining Technology Conference, The Australasian Institute of Mining and Metallurgy, Melbourne, pp. 43–52.

Kurth, H. (2013). Real time on-belt elemental analysis using PGNAA for mineral processing plant control, Proceedings Procemin2013: 10th International Mineral Processing Conference 15–18 October 2013, Santiago, Chile, Gecamin, Santiago.

Kurth, H., & Balzan, L. (2017). Assessing bulk sorting suitability at the New Afton Mine, Proceedings of Metallurgical Plant Design and Operating Strategies (MetPlant 2017), Perth, WA. The Australasian Institute of Mining and Metallurgy, Melbourne. pp. 315–323.

Kurth, H., & Edwards, M. (2008). Use of on-belt analysers for improved process control of conveyed materials, Proceedings Metallurgical Plant Design and Operating Strategies (MetPlant 2008), Perth, WA. The Australasian Institute of Mining and Metallurgy, Melbourne, pp. 493–507.

Nadolski, S., Klein, B., Samuels, M., Hart, C.J.R., & Elmo, D. (2018a). Evaluation of cave-to-mill opportunities at the New Afton Mine, Proceedings of the 50th Annual Canadian Minerals Processors Operators Conference, Ottawa, Ontario, 23-25 January 2018. Danyliw, B., Cameron, R., and Zinck, J. (eds.). Canadian Institute of Mining, Metallurgy and Petroleum, Montreal. pp. 270–281.

Nadolski, S., Samuels, M., Klein, B., & Hart, D. (2018b). Evaluation of bulk and particle sensor-based sorting systems for the New Afton block caving operation, Minerals Engineering, 121. 10.1016/j.mineng.2018.02.004.

Patel, M. (2014). On-belt elemental analysis of lead-zinc ores using prompt gamma neutron activation analysis. Proceedings XXVII International Mineral Processing Congress (ch. 17). Santiago, Chile: Gecamin.

Henry Kurth, Chief Marketing Officer and Minerals Consultant

Scantech International Pty Ltd, Adelaide/Australia

Henry Kurth has a degree in Geology from Queensland Institute of Technology (now QUT − Qld University of Technology) and has 15 years’ experience in mining geology roles in coal, gold and base metals operations. The next 7 years were in technical sales roles to the resources sector and the last 14 years with Scantech where he leads the global minerals marketing and sales functions in his current role as Chief Marketing Officer and Minerals Consultant. He has been a member of the AusIMM for over 35 years and is a member of the SME in USA and CIM in Canada. Henry Kurth has presented at more than 25 major minerals conferences and workshops on real time analysis technology applications.